Table of Contents

REACH compliance isn’t just a regulatory burden—it’s a strategic advantage. For global manufacturers and OEM suppliers, navigating REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) compliance across decentralized supplier networks can feel overwhelming. But getting it right can unlock access to EU markets, build stakeholder trust, and future-proof your operations.

Let's break down how to operationalize REACH compliance across your value chain—while saving time, reducing risk, and staying audit-ready.

Understanding REACH Supply Chain Obligations

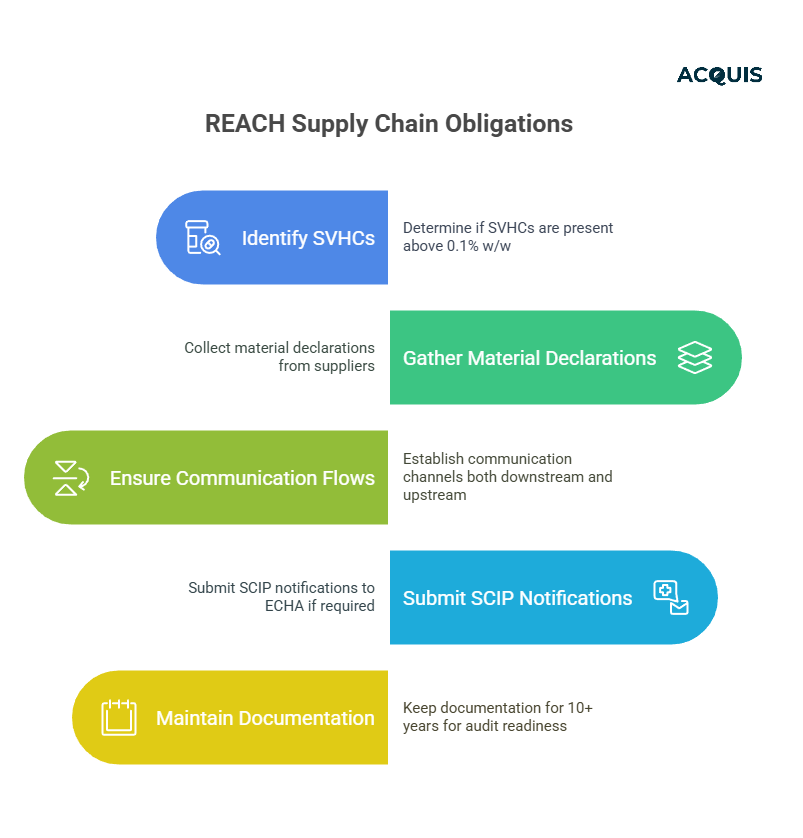

If you’re placing articles, substances, or mixtures on the EU market, you’re expected to:

- Know whether any SVHCs (Substances of Very High Concern) are present above 0.1% w/w

- Gather full material declarations or component-level data from suppliers

- Ensure communication flows both downstream and upstream

- Submit SCIP notifications to ECHA (if applicable)

- Maintain documentation for 10+ years for audit readiness

Whether you're a non-EU OEM, importer, or assembler, you are liable for ensuring the products you ship into the EU meet REACH obligations.

Step-by-Step: Implementing REACH Compliance in Your Supply Chain

1. Map Your Supply Chain at the Article Level

Start by identifying every material and article in your products. Classify them based on:

- Source location

- Risk profile (e.g., electronics, coatings, polymers)

- Known SVHC exposure potential

"If you don’t know what’s in your product, you can’t prove compliance."

2. Digitize Supplier Engagement

Manual surveys and email threads won’t scale. Invest in tools that:

- Automate FMD (Full Material Disclosure) collection

- Standardize submissions via IPC-1752A, IEC 62474

- Track supplier response rates and data validity

3. Screen for SVHCs in Real Time

Use an automated engine to screen BOMs and supplier data against the latest REACH SVHC list (updated bi-annually). Proactively flag:

- SVHCs above 0.1% w/w

- Gaps in material composition

- Missing supplier declarations

4. Prepare for SCIP Reporting

If your product contains SVHCs above threshold:

- Create a SCIP dossier for each article

- Include material identifiers, concentration, safe use instructions

- Submit via ECHA portal or system-to-system (S2S)

5. Align Internal Teams

Train sourcing, compliance, and engineering teams on:

- REACH regulation updates

- SVHC impacts on product design

- How to use compliance tools effectively

Why Most Companies Fall Short (And How to Avoid It)

- Outdated supplier data: Many rely on static spreadsheets

- Missed updates: SVHC list changes every 6 months

- No audit trail: Inadequate documentation or version control

Solution: A centralized REACH platform with version tracking, supplier scoring, and real-time risk alerts.

Let's Operationalize REACH Compliance

Acquis helps OEMs and global manufacturers simplify and scale REACH compliance. Our end-to-end solution:

- Automates supplier outreach and validation

- Tracks compliance across every BOM

- Prepares SCIP dossiers instantly

- Keeps you updated on regulatory changes

Don’t wait for an audit or EU market disruption to get REACH ready.