Table of Contents

Let’s be honest.

If you’re in electronics and still treating PFAS like a future problem, you’re not paying attention. These chemicals—used in everything from semiconductors to solder masks—are now at the center of a global regulatory storm.

Regulators aren’t just circling anymore. They’ve landed.

PFAS 101: Not Just Another Acronym

PFAS stands for Per- and Polyfluoroalkyl Substances—a family of synthetic chemicals with strong carbon-fluorine bonds that don’t break down. Ever.

That’s what makes them useful. That’s also what makes them dangerous.

And no, this isn’t one chemical. It’s a moving target:

- OECD lists ~4,700

- EPA lists over 12,000

- Maine? Their own list.

If your compliance team is still asking, “Which PFAS?”—you’ve got a problem.

Where PFAS Hides in Electronics

PFAS doesn’t show up on labels, but it’s everywhere behind the scenes:

- PCB coatings for dielectric strength

- Semiconductors for etching and heat resistance

- Hard drive lubricants

- Cables and wire jackets for thermal insulation

- Displays (LCD/OLED) to repel moisture

- Aerospace electronics where failure isn’t an option

If it needs to insulate, repel, resist, or just work longer—there’s probably PFAS in it.

Why Regulators Are Cracking Down

This isn’t just about emissions or greenwashing.

PFAS has been found in:

- Rainwater. Everywhere.

- Breast milk. Worldwide.

- Newborns. Let that sink in.

The health links? Not good.

- Cancer (testicular, kidney)

- Liver damage

- Reproductive harm

- Immune suppression

- Sky-high cholesterol

And because PFAS doesn’t degrade, every gram ever made is still out there.

Regulations in 2025: Welcome to the Squeeze

PFAS in the U.S.

- TSCA 8(a)(7): You will report PFAS use by May 2025 if you manufacture or import electronics. No exemptions for articles.

- State rules: Maine, Minnesota, California are tightening faster than federal.

- EPA’s water standards: Not aimed at you, but will catch you if you discharge wastewater.

PFAS in the EU

- REACH PFAS Ban: Full PFAS restriction proposal. Covers every PFAS unless exempted.

- POPs Regulation: PFOA, PFOS? Already gone.

- Drinking Water Directive: More indirect pressure on manufacturers.

PFAS in Canada

- CEPA 2025 Section 71: Targeting long-chain PFAS. Includes imported electronics.

In short: Even if you don’t sell in all these markets, your suppliers probably do.

What’s the Risk in Electronics?

Most electronics companies don’t even realize they’re exposed. If PFAS shows up in coatings, adhesives, or materials you didn’t spec—guess who’s still on the hook?

It’s you.

And non-compliance? That means:

- Product bans

- Brand damage

- Lost contracts

- Fines you didn’t budget for

What You Need to Do — Yesterday

1. Screen Your BOMs

Start with the usual suspects: PCBs, cables, adhesives, coatings. PFAS could be hiding in your stack.

2. Push Your Suppliers

Get Full Material Declarations. If they dodge? Escalate. Replace them. This isn’t optional anymore.

3. Test Where You Can’t Trust

Use labs. LC-MS/MS. Know what’s in your product before the regulators do.

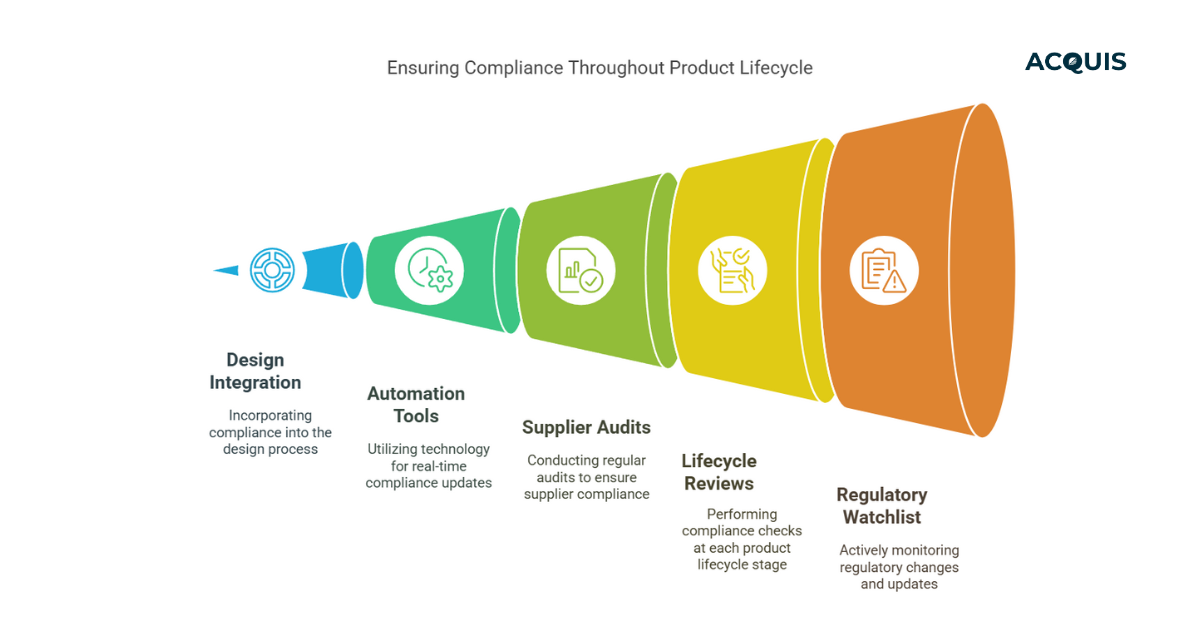

4. Track the Right Regulations

REACH Annex XVII. TSCA. Maine laws. CEPA. If you don’t know what applies—you’re exposed.

5. Build PFAS Into Your EHS Program

It’s not just a chemical issue. It’s a product stewardship, sales enablement, and brand resilience issue now.

Where This Is Going

The EU’s about to restrict all PFAS in electronics. Maine already demands reporting. Customers are asking for disclosures. And regulators? They’re not bluffing.

PFAS isn’t just an environmental risk. It’s a business continuity risk.

And the ones who prepare now? They win.

Need Backup to stay safe and compliant with PFAS?

We help electronics manufacturers turn PFAS chaos into compliance clarity.

At Acquis, we offer:

- Material screening automation

- Supplier declaration tools

- TSCA/REACH readiness

- Custom PFAS risk scoring

No fluff. No guessing. Just clear, fast answers.