Table of Contents

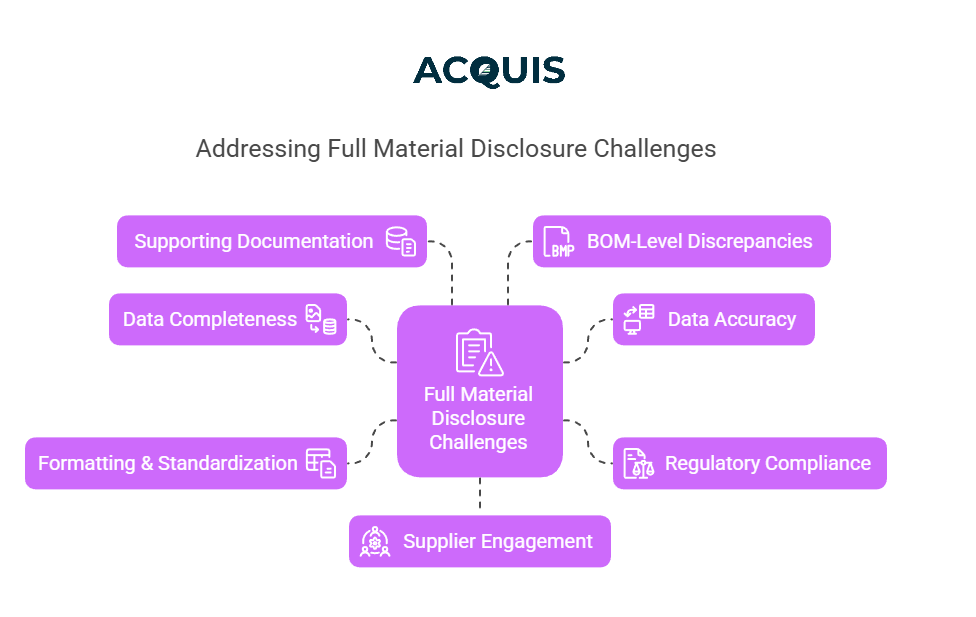

You’ve committed to Full Material Disclosure (FMD). Good. That means you’re thinking beyond checkboxes and aiming for real transparency. But let’s be honest — collecting FMDs from your supply chain isn’t exactly plug-and-play.

At Acquis, we’ve helped companies handle thousands of FMDs, and Irrespective of industry, the same core challenges pop up again and again. Lets explore the top FMD headaches and what you can actually do to fix them.

Data Completeness Issues in FMD

This is where it all starts and often stalls. Suppliers submit partial declarations, leave out key materials, or skip CAS numbers like they’re optional.

The common culprits of Full Material Disclosure:

- Missing substance-level breakdowns

- No CAS numbers or weight percentages

- Incomplete material declarations for multi-part components

- Process substances (e.g., coatings, adhesives) conveniently “forgotten”

Fix it: Set expectations early. Require a minimum completeness level (we suggest 90%+) and always follow up for missing CAS numbers. For recurring gaps, consider mapping from SDS or engineering drawings as a starting point.

Data Accuracy Issues in FMD

Sometimes you get the data, but it’s just… wrong. CAS numbers that don’t match the substance name, percentages that don’t add up, or a total part weight that seems to defy physics.

What common error do we see a lot in Full Material Disclosure

- Wrong or outdated CAS numbers

- Mismatched substance names vs. IDs

- Rounding or unit errors (hello, milligrams vs. grams)

- Totals that don’t match BOM values

Fix it: Use automated validation tools that flag discrepancies on import. Manual review is not scalable. Trust us, you don’t want to VLOOKUP your way through 500 parts.

Regulatory Non-Compliance

Here’s where incomplete or inaccurate FMDs start to hurt. Substances that exceed legal thresholds. Exemptions that aren’t justified. Supplier declarations that haven’t been updated since 2019.

Watch out for these using Full Material Disclosure for compliance:

Restricted substances (e.g., RoHS, REACH SCIP, Prop 65, POPs)

- Unverified exemptions

- Missing updates as new SVHCs or RoHS substances are added

Fix it: Automate cross-checking against live substance lists. If your system can’t flag a newly added SVHC, you’re flying blind. Require suppliers to confirm exemption applicability in writing (no guesswork allowed).

Formatting & Standardization Issues in Full Material Disclosure

Here’s a fun one: 20 suppliers, 20 formats. Some send PDFs, some Excel, others outdated XML. You end up stitching things together like a regulatory jigsaw puzzle.

Big problems:

- Non-compliant IPC-1752A files

- Outdated versions (e.g., 1.1 instead of 2.0)

- Custom material names (“shiny metal” ≠ valid material class)

- Duplicate substances declared multiple ways

Fix it: Ask for data in structured formats (IPC 1752A, IMDS, IEC 62474), and use a platform like Acquis Compliance Tool to bring everything into one system-readable format. Standardization is how you scale.

Missing Supporting Documentation in Full Material Disclosure

Data without documentation is just storytelling.

Often missing:

- CoC/DoC (Certificate of Compliance/Conformity)

- SDS for chemical materials or coatings

- Third-party lab reports (SGS, Intertek, etc.)

- Evidence supporting exemption claims

Fix it: Build documentation requirements into your data request process. Store it alongside the FMDs — not in a separate email chain from six months ago.

BOM-Level Discrepancies in Full Material Disclosure

Even if the FMD is perfect, it can still fall apart at the BOM level. We’ve seen it all — materials mapped to the wrong components, duplication, and worse, no linkage at all.

Typical issues:

- Materials incorrectly assigned to components

- BOM doesn’t match declared substances

- Subcomponents declared twice or not at all

- Engineering specs and FMDs that tell two different stories

Fix it: Integrate your engineering BOM with your compliance system. Run alignment checks regularly. And please — don’t manage this manually in spreadsheets.

Supplier Engagement Issues in Full Material Disclosure

This is the elephant in the room. Even with all your systems and standards in place, you still need one thing: your supplier to cooperate.

Challenges include:

- Long delays or no response at all

- “We don’t know how” replies

- “Sorry, that’s confidential” shutdowns

- Global language and regulatory knowledge barriers

Fix it:

- Offer training, templates, and tools to make it easy for suppliers.

- Accept partial FMDs where appropriate, but always ask for confirmation on the 10% confidential gap.

- Update your procurement terms to require FMDs at onboarding — not after the fact.

Some Other Challenges You Need to Think About:

- Data Lifecycle Management Even accurate FMDs can go stale. If a supplier gave you data in 2022 and REACH added 10 new SVHCs since then — that file’s outdated.

- Process Substance Blind Spots Many FMDs skip substances used in production (like coatings or adhesives), which can still trigger non-compliance under REACH, Prop 65, or TSCA.

Fix it: Set a schedule for annual or bi-annual FMD refreshes. And don’t treat process chemicals as optional — they're often where the risks hide.

Final Words on Full Material Disclosure Challenges:

FMD is not a one-and-done exercise. It’s a continuous process that gets better (and more useful) the more you refine it. The key isn’t perfection — it’s visibility. If you can see what’s in your product, you can manage risk, reduce cost, and stay one step ahead of compliance chaos.

Next Up: Why FMD is a Smart Business Investment (Even If You’re Not in Compliance)

We’ll learn the ROI behind FMD — from cost savings and risk reduction to smoother customer audits and ESG reporting wins. Want that post in your inbox early? You know what to do.