Table of Contents

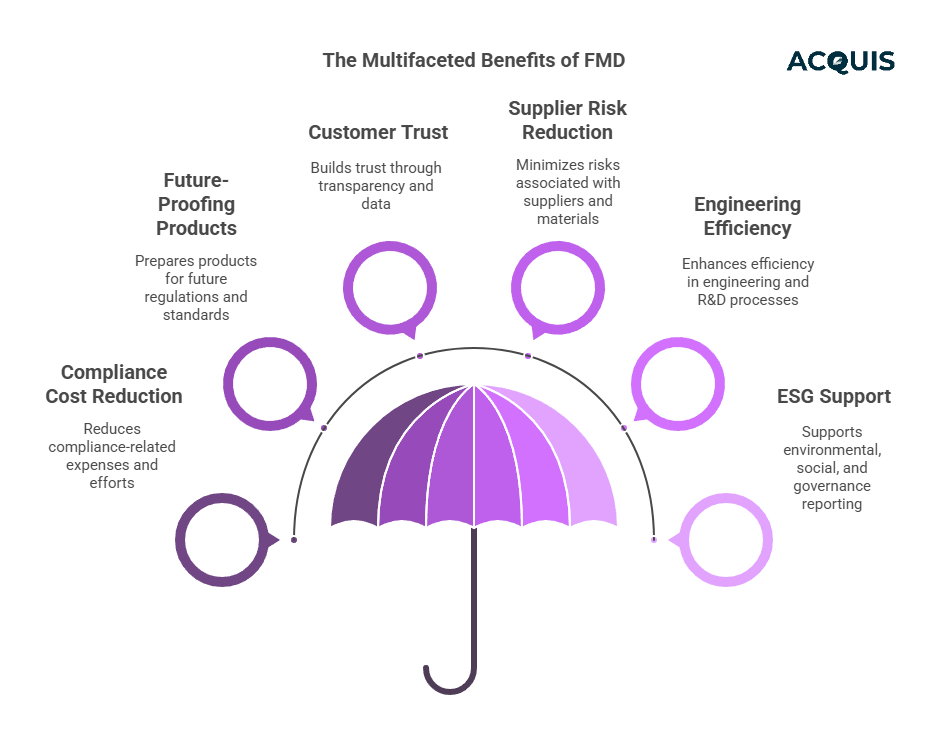

Let’s get one thing straight: FMD isn’t just for compliance teams.

It’s a strategic move for anyone serious about risk, sustainability, or building a future-ready supply chain. You don’t need to be a regulatory expert to care about what’s in your product. You just need to care about running a smart, scalable business.

So... Why Invest in FMD?

Let’s break it down.

1. FMD Cuts Your Compliance Costs — Big Time

Every time REACH adds a new SVHC or RoHS tightens a limit, most companies do the same thing: Scramble to contact suppliers. Wait for updated declarations. Pray the data is accurate. With FMD?

- You already have the data.

- You run an automated scan.

- You see the risk.

- You act fast.

Translation:

- Fewer supplier touchpoints

- No last-minute firefighting

- Lower legal exposure

- Massive savings in compliance admin time

Less time chasing declarations = more time building products.

2. It Future-Proofs Your Products

If you’re still chasing down basic declarations today, how are you going to handle:

- Digital Product Passports (coming in hot from the EU)?

- Lifecycle-based sustainability reporting?

- Scope 3 emissions audits?

FMD gives you chemical-level visibility. That’s the foundation for:

- Eco-design initiatives

- Carbon footprint modeling

- Product-level ESG reporting

In short, it’s your way of saying:

“We know exactly what goes into our products — and we’re ready for what’s next.”

3. FMD Builds Customer Trust

B2B buyers are getting smarter — and more demanding. They want proof, not promises. And they’re building FMD into their procurement checklists.

- Want to land big OEM contracts?

- Want to pass customer audits without sweating?

Show them you're proactive. Show them the data. Show them FMD.

4. It Reduces Supplier Risk

Suppliers come and go. Materials change. Substances get regulated.

If you don’t have full disclosure, you’re flying blind.

But with FMD, you can:

- Validate materials before onboarding a new supplier

- Avoid parts with restricted substances during sourcing

- Catch compliance red flags before they bite you in production

- Smart procurement starts with smart data.

5. It Boosts Engineering and R&D Efficiency

Your engineers shouldn’t have to wonder what’s in a component.

With FMD, they know — upfront.

That means:

- Faster material selection

- Fewer redesigns due to compliance issues

- Better choices for sustainable product design

FMD isn’t just for compliance. It’s fuel for smarter engineering.

6. It Supports ESG Reporting & Circular Economy Goals

If you're reporting on sustainability — or even thinking about it — FMD is non-negotiable.

Carbon footprint data?

- You need to know your material composition.

Recycling readiness?

- You need to know what substances might interfere.

Supply chain transparency?

- Starts with knowing what you're sourcing.

FMD isn’t just a checkbox. It’s your data backbone for ESG.

Bottom Line: Whether you’re in compliance, engineering, sourcing, or sustainability —

FMD pays for itself.

Not just in cost savings, but in agility, trust, and long-term resilience.

- You don’t have to wait for a mandate.

- You don’t need a task force.

- You just need to get started.

Next Up: Tools That Make FMD Less of a Headache (And More of a Superpower) we’ll walk you through how to simplify FMD collection, validation, and reporting using free tools — including the one we just launched.