Table of Contents

If compliance were a detective story, data would be the smoking gun. It’s the difference between confidently declaring compliance and nervously hoping no one asks too many questions.

Regulatory compliance—whether it’s REACH, RoHS, Prop 65, TSCA ,PFAS, or Conflict Minerals—relies on accurate, up-to-date data. Yet, too many companies struggle with incomplete supplier responses, outdated Bill of Materials (BOM) records, and missing full material disclosures (FMD).

Let's learn how to enhance data coverage for compliance, improve supplier response rates, and ensure your data works for you—not against you.

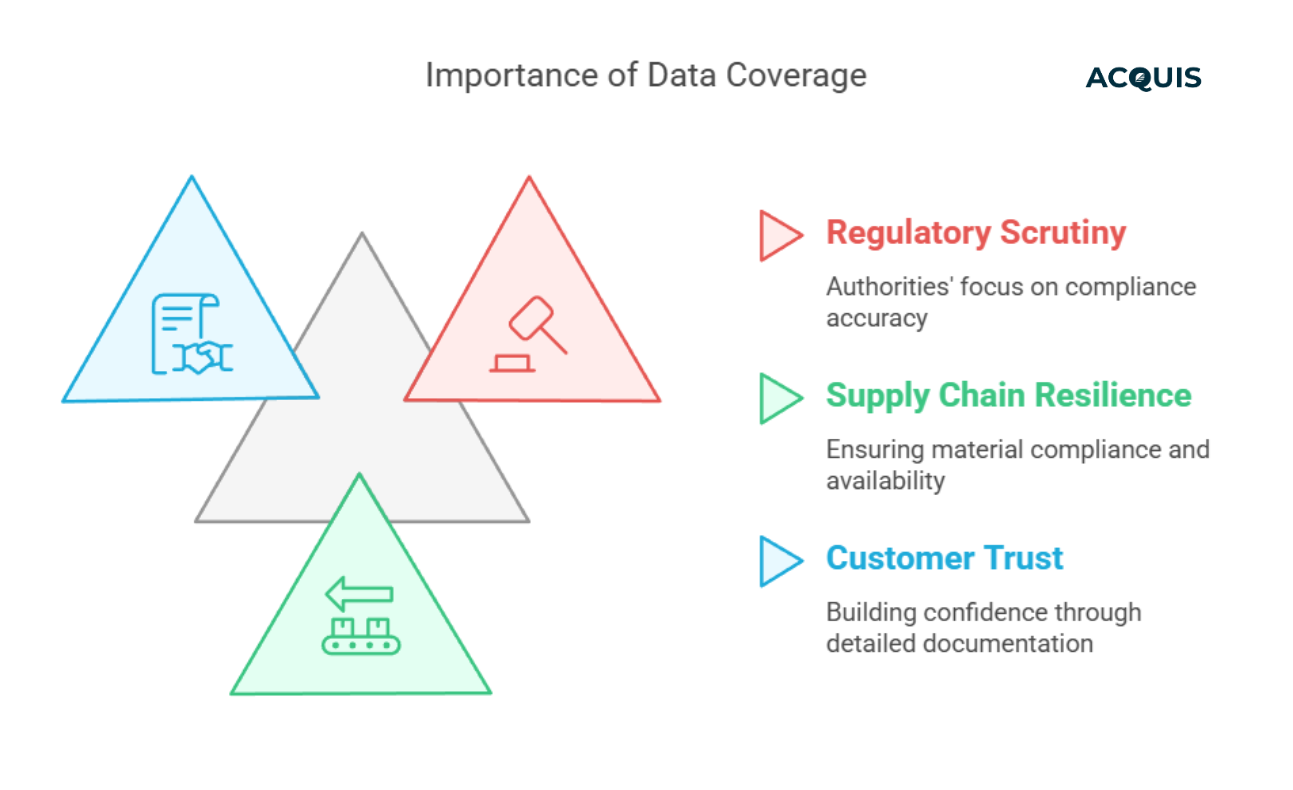

Why Data Coverage Matters

Many companies think compliance is just about collecting declarations. But let’s be real—bad data is as dangerous as no data. If a supplier sends you a half-baked compliance document full of generic statements, you’re still on the hook.

Here’s why data coverage is crucial:

- Regulatory Scrutiny: Authorities are cracking down on vague or incomplete compliance claims & greenwashing.

- Supply Chain Resilience: If you lack full material disclosure (FMD), you may scramble to replace non-compliant components at the last minute.

- Customer Trust: OEMs and end-users expect detailed compliance documentation—without it, you risk losing contracts.

Having strong data coverage means you know exactly what’s in your products—no surprises, no scrambling.

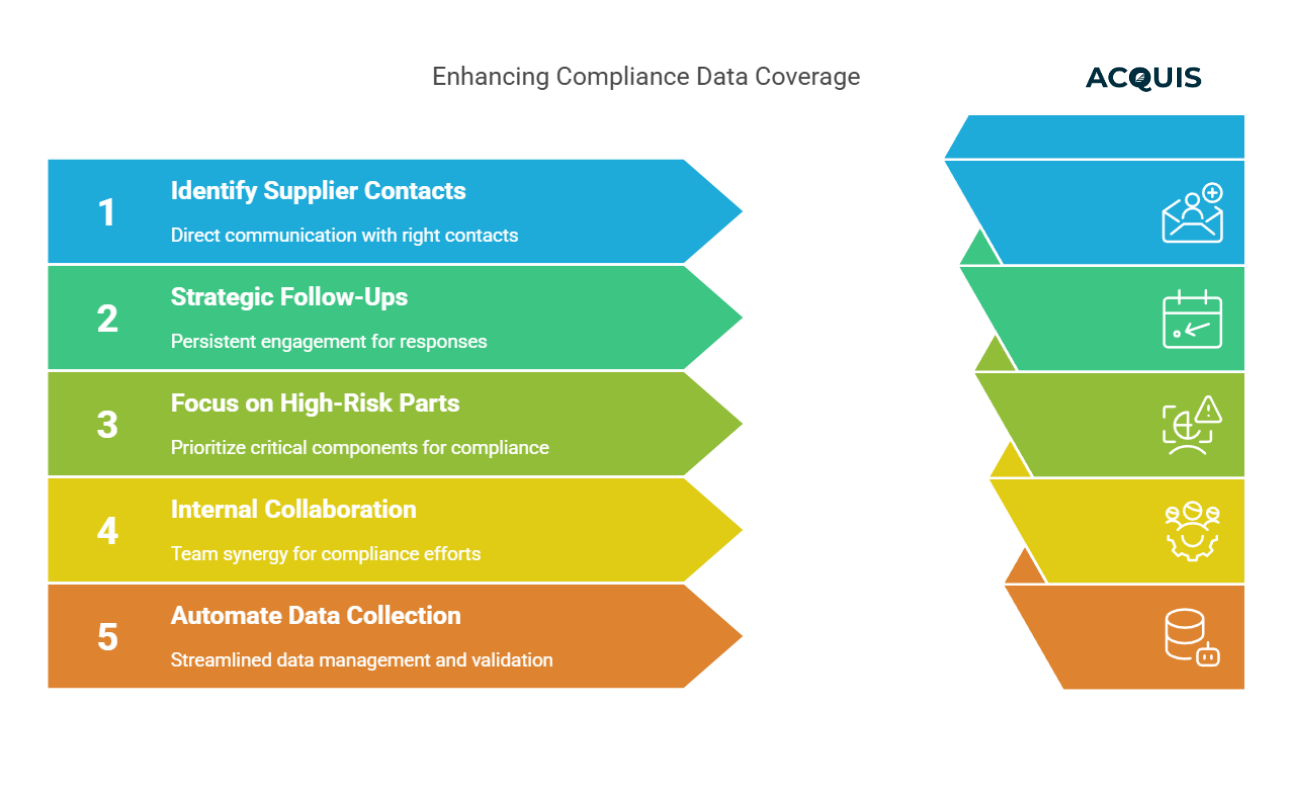

How to Improve Data Coverage

Enhancing data coverage isn’t just about asking suppliers more often—it’s about asking smarter. Here’s how to do it:

1. Identify the Right Supplier Contacts

Stop sending compliance requests to the wrong people! A common mistake is directing emails to sales representatives or general support inboxes.

What to do instead:

- Find the compliance or regulatory affairs team at each supplier.

- Establish direct points of contact to improve response rates.

- Build a supplier compliance contact database to ensure requests reach the right people every time.

2. Follow Up Strategically

Many suppliers won’t respond to your first email. That doesn’t mean they’re ignoring you—it just means compliance is not their top priority.

Best practices for follow-ups:

- Schedule structured reminders (e.g., 1 week, 2 weeks, 1 month).

- Use a mix of emails and phone calls—sometimes, a quick call gets results.

- Have your procurement team escalate requests if suppliers remain unresponsive.

3. Focus on Custom & High-Risk Parts

Some components present higher compliance risks than others. Custom parts and specialized materials often have little publicly available compliance data, making them harder to verify.

How to handle them:

- Prioritize high-risk materials (e.g., coatings, adhesives, plastics, specialty metals).

- Work with engineering teams to define materials where compliance uncertainty exists.

- Allocate resources for testing if necessary.

4. Leverage Internal Collaboration

Compliance isn’t just your responsibility—it requires input from procurement, engineering, and supply chain teams.

Why this matters:

- Procurement teams (Buyers) have direct relationships with suppliers and can push for better responses.

- Engineers can identify alternative components if compliance risks arise.

- Supply chain teams can track supplier performance on compliance metrics.

If compliance is operating in a silo, data coverage will always be an uphill battle.

5. Automate Compliance Data Collection

Manually chasing down supplier responses and tracking compliance data in spreadsheets is a recipe for failure.

What you need:

- A centralized compliance platform to manage data requests and supplier responses.

- Automated reminders to follow up on missing declarations.

- AI-driven data validation to flag discrepancies in supplier documents.

Companies that automate compliance data collection reduce administrative workload and improve supplier response rates by 30-50%.

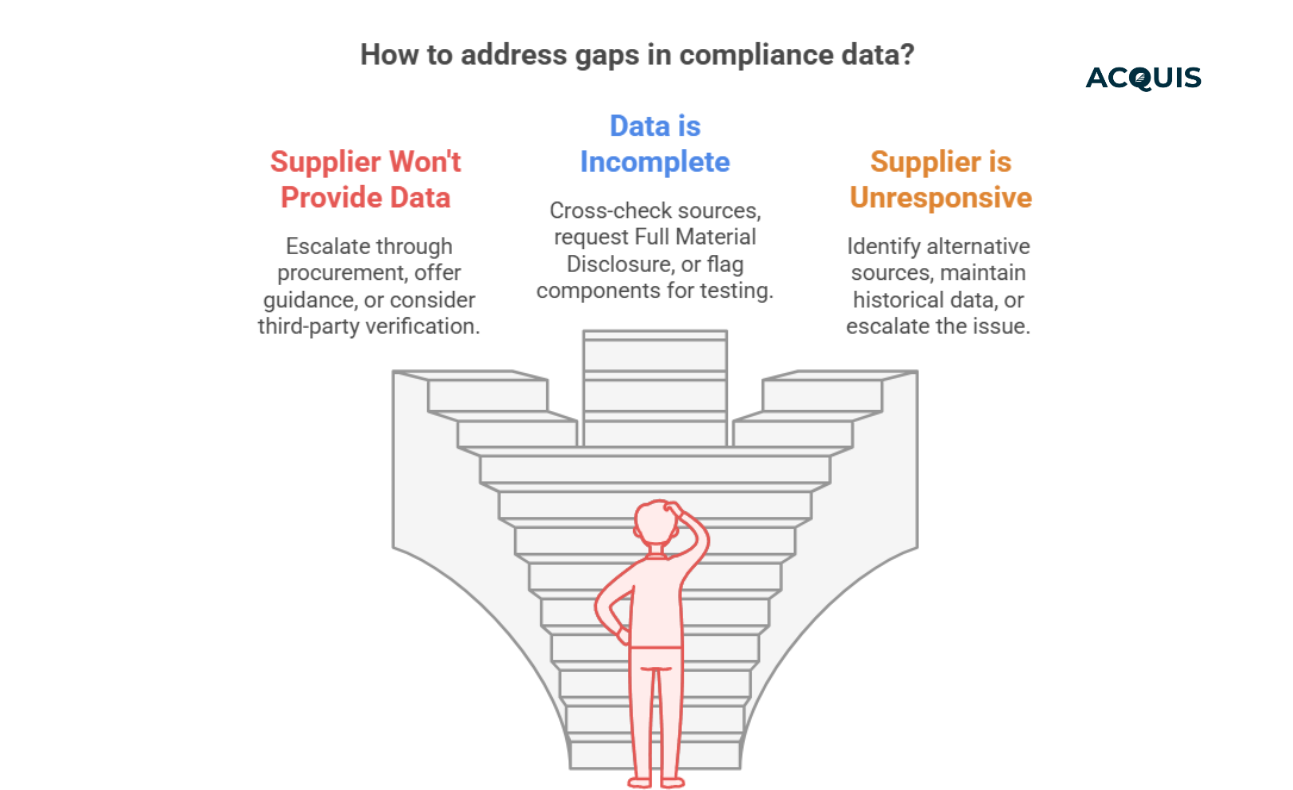

Overcoming Common Data Gaps

Even with the best strategies, gaps in compliance data happen. Here’s how to handle them:

Scenario 1: The Supplier Won’t Provide Data

- Escalate through procurement—remind suppliers of contractual compliance obligations.

- Offer guidance—some suppliers need help understanding regulatory requirements.

- Consider third-party verification—testing may be necessary if supplier data is unavailable.

Scenario 2: The Data is Incomplete

- Cross-check with existing sources—sometimes, material standards used & regulatory information might be available in design drawings, SDS/MSDS, Distributor website etc.

- Ask for Full Material Disclosure (FMD) instead of just compliance statements.

- Flag high-risk components for lab testing.

Scenario 3: The Supplier is Unresponsive

- Identify alternative sources—work with procurement/component engineering to find compliant replacement parts.

- Maintain historical supplier data—if a supplier previously provided data, use it to analyze non-compliance risk.

- Escalate the issue—if necessary, involve legal or executive leadership.

Compliance Success Starts with Data

If you want to be proactive rather than reactive, improving data coverage is step one. When compliance data is complete, accurate, and easily accessible, your business runs smoother, your supply chain is stronger, and regulatory audits become non-events.

So, take a step back—do you have gaps in your compliance data? If so, now’s the time to act.

Learn Maximizing Supplier Engagement for Long-Term Compliance Success—because data coverage is only half the battle. Getting suppliers to actively participate is what separates the best compliance programs from the rest.

So, take a step back—do you have gaps in your compliance data? If so, now’s the time to act.

Learn about Long-Term Compliance Success—because data coverage is only half the battle. Getting suppliers to actively participate is what separates the best compliance programs from the rest.