Table of Contents

The Conflict Minerals Reporting Template (CMRT) is a standardized tool designed to help companies collect and disclose data on the use of conflict minerals—tin, tungsten, tantalum, and gold (3TG)—in their supply chains. Managed by the Responsible Minerals Initiative (RMI), the CMRT aligns with the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (CAHRAs).

What is the Purpose of the CMRT?

The CMRT is a global tool used across industries to promote supply chain transparency and compliance with conflict minerals regulations. Its primary purposes include:

- Data Collection: Facilitating the collection of supplier data on 3TG minerals within the supply chain.

- Compliance Reporting: Helping companies meet the requirements of the U.S. Dodd-Frank Act Section 1502 and the EU Conflict Minerals Regulation.

- Public Disclosure: Enabling businesses to disclose sourcing information to investors, customers, and other stakeholders.

- Smelter Identification: Supporting the RMI’s Responsible Minerals Assurance Process (RMAP) by identifying new smelters and refiners for potential audits.

The latest CMRT version (6.4), released in April 2024, includes bug fixes, updates to smelter lists, and enhanced formatting for improved usability.

Who Needs to Report on Conflict Minerals?

Companies required to report on conflict minerals include:

- U.S. Companies: Public companies under the Dodd-Frank Act Section 1502 that manufacture products containing 3TG minerals.

- EU Importers: Companies importing conflict minerals into the EU under the EU Conflict Minerals Regulation (Regulation 2017/821), particularly from CAHRAs.

Download our Conflict Minerals eBook to learn more about Responsible sourcing in detail.

Both regulations require companies to conduct due diligence on their supply chains and disclose the origin of their conflict minerals annually. The RMI recommends updating the CMRT at least once a year to maintain accurate and transparent supply chain data.

What Information is Required to Complete a CMRT?

The CMRT template consists of eight sheets, some of which provide instructions, while others require supplier input. The data collected falls into four main categories:

-

Company Information:

- Supplier details, including company name, contact information, and reporting year.

-

Due Diligence Information:

- Questions related to the use of 3TG minerals, regulatory applicability, and the supplier’s responsible sourcing efforts.

-

Product List:

- A reference to part numbers and product-level declarations.

-

Smelter List:

- Identification of smelters and refiners used in the supply chain, including their location and certification status.

Step-by-Step Guide to Completing the CMRT

- Download the Template: Access the latest CMRT version from the RMI website to ensure compliance with current standards.

- Gather Company Information: Compile your company’s details, including contact information and reporting year.

- Identify Suppliers: List all suppliers involved in the use of 3TG minerals and gather their contact information.

- Define Product Scope: Specify the products subject to reporting, including categories and models.

- Request Smelter Information: Collect details about smelters and refiners, including their name, location, and materials processed.

- Document Due Diligence: Ask suppliers to share information about their responsible sourcing measures, including policies, surveys, and audits.

- Trace Mineral Origin: Determine the countries of origin for all 3TG minerals used in your products.

- Validate Data: Ensure all collected information is accurate, complete, and consistent with your records.

- Compile Reports: Consolidate supplier data into a single CMRT submission, ready for internal or external reporting.

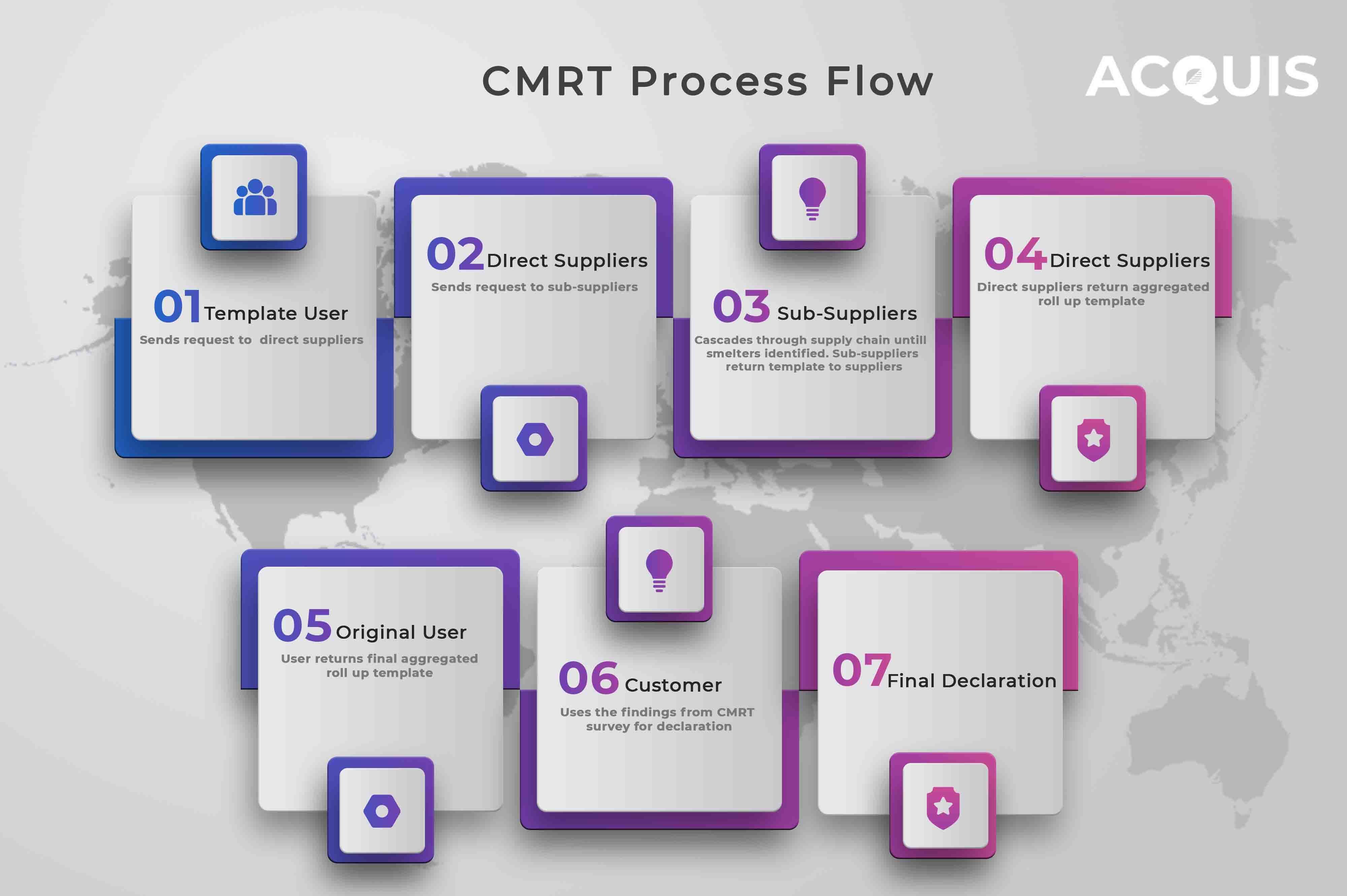

Here is how CMRT data flows within different stakeholders in the supply chain:

What is the Difference Between CMRT and EMRT

While the CMRT is used for reporting on 3TG minerals, the Extended Minerals Reporting Template (EMRT) focuses on other materials like cobalt and mica. Key differences include:

- Mandatory vs. Voluntary: The CMRT is mandatory for companies under conflict minerals regulations, while the EMRT is voluntary, typically used to meet sustainability goals.

- Minerals Covered: CMRT addresses 3TG, whereas EMRT covers extended minerals outside the conflict minerals category.

How Acquis Can Help with CMRT Reporting

The Acquis Compliance Tool simplifies conflict minerals reporting with a suite of features tailored to meet regulatory requirements:

- Automated Data Collection: Streamline the CMRT process with automated supplier outreach and smelter risk analysis.

- Multilingual Support: Overcome language barriers to improve supplier engagement and response rates.

- Data Visualization: Generate exportable reports and dashboards for internal and external stakeholders.

- Regulatory Expertise: Access guidance from in-house compliance experts to ensure accuracy and compliance with evolving regulations.

- Scalability: Adapt to additional reporting needs, such as EMRT and STRT, as your business grows.

With Acquis, you can gain supply chain visibility, reduce risks, and meet compliance standards efficiently. Take the first step toward responsible sourcing today. Contact us to learn how Acquis can transform your compliance journey.