Table of Contents

Let’s not sugarcoat it:

Collecting Full Material Disclosures (FMDs) is 50% data management...

and 50% supplier wrangling.

If you’ve ever sent 10 emails to the same supplier and gotten back a blurry PDF with the wrong part number you already know. The best tools in the world won’t help if your suppliers don’t deliver the data.

That’s why you need a supplier engagement strategy not just a spreadsheet and good intentions.

Here’s how to build Full Material Disclosures Data that actually works.

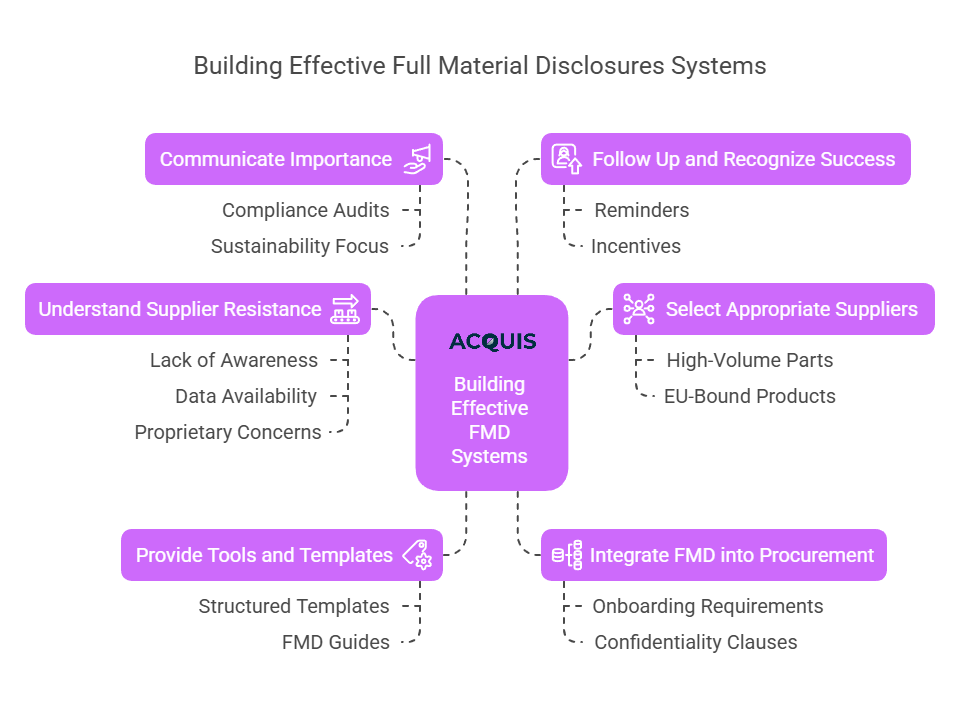

Step 1: Understand Why Suppliers Push Back

Before you fix it, understand the friction. Here’s why most suppliers don’t hand over FMD data easily:

- They don’t know what FMD is

- They don’t have the data readily available

- They’re afraid of exposing proprietary info

- They think declarations are “good enough”

- No one’s ever asked them before

And honestly? Most are already drowning in customer requests.

Your job is to make it easier to say yes.

Step 2: Start with the Right Suppliers

Don’t try to boil the ocean. Begin with:

- High-volume parts

- EU-bound products

- Suppliers with known risk (e.g., electronics, coatings, adhesives)

- Suppliers already providing CoCs or regulatory declarations And focus on off-the-shelf component vendors first they often already have FMD data. You just have to ask.

Step 3: Equip Them with Tools and Templates

Don’t just send an email saying “Please provide FMD.” That’s a guaranteed route to confusion or silence. Instead, give them:

- A structured template (Excel or IPC 1752A format)

- A short FMD guide or FAQ

- Access to a free FMD tool (like ours) that helps them validate and export in XML

- A reasonable deadline + contact support

Suppliers are more likely to engage if they feel supported, not just demanded.

Step 4: Build FMD into Your Procurement Process

This is a game-changer. Update your supplier onboarding docs to include:

- A requirement to provide FMDs

- A clause allowing limited confidentiality (e.g., “up to 10% proprietary”)

- A schedule for regular updates (e.g., annually or when parts change)

- A channel for submitting structured data

When FMD becomes part of the contract, you won’t have to chase later.

Step 5: Communicate the “Why”

Suppliers aren’t going to jump through hoops for fun. So let them know why FMD matters — and what’s in it for them:

- It reduces back-and-forth in future compliance audits

- It protects both parties in case of enforcement

- It strengthens the relationship with sustainability-focused customers

- It future-proofs their own business for ESG and DPP requirements

Make it about partnership not policing.

Step 6: Follow Up and Celebrate the Wins

- Send reminders not spam

- Track submissions and flag gaps

- Give shoutouts to suppliers who provide clean, validated FMDs

- Share how that data helped you solve a real compliance or sustainability challenge

Incentivize participation. Build goodwill.

Final Word:

You don’t need to chase suppliers forever.

You just need a system.

Build FMD into your onboarding, give them the tools, and speak their language.

Because in the end, supplier engagement isn’t just about compliance —

It’s about building a smarter, more resilient supply chain.

Want to fast-track your FMD program? Our Acquis FMD tool is made for suppliers too — send them the link, and you’ll get data back that actually works.