Table of Contents

What Is Korea RoHS?

The Act for Resource Recycling of Electrical and Electronic Equipment and Vehicles — commonly known as Korea RoHS (K-RoHS) — is not just RoHS. It’s a unified regulation that rolls in EU-style RoHS, WEEE, and ELV into a single, enforceable compliance mandate for electronics and vehicles sold in South Korea.

Originally passed in 2007 and enforced from July 1, 2008, K-RoHS aims to restrict hazardous substances and drive resource recycling for both EEE and automobiles.

And as of 2025, the regulation is expanding dramatically — from a product list of 49 to nearly all electrical and electronic products.

Covered Products: What Falls Under Korea RoHS in 2025

Initially limited to TVs, PCs, appliances, mobile devices, and printers, the list has grown to 49 products (via Decree No. 31184) and is now expanding to nearly all EEE products sold in South Korea.

Products newly included since 2021:

- Dehumidifiers

- Toasters, kettles, fryers, coffee makers

- Electric massage machines

- Gaming consoles and routers

- Treadmills and projectors

- Vending machines, hot pots, sewing machines

2025 Update: The Korean Ministry of Environment announced that all EEE (with limited exemptions for industrial, military, or low-volume products) will be regulated under RoHS and EPR by end of 2025.

Restricted Substances & Thresholds of Korea RoHS

| Substance | Max Limit (wt%) | | -------------------------- | --------------- | | Lead (Pb) | 0.1% | | Mercury (Hg) | 0.1% | | Cadmium (Cd) | 0.01% | | Hexavalent Chromium (Cr⁶⁺) | 0.1% | | PBBs | 0.1% | | PBDEs | 0.1% | | DEHP | 0.1% | | BBP | 0.1% | | DBP | 0.1% | | DIBP | 0.1% |

The four phthalates were added in 2021, and thresholds apply at the homogeneous material level — same as EU RoHS 3.

Korea RoHS: Key Requirements

Manufacturers and importers must:

- Declare compliance with substance limits

- Provide product labeling and markings

- Submit technical documentation

- Share recycling info with consumers

- Meet recycling rate targets

South Korea enforces an annual recycling rate and mandates:

- Product designs must support disassembly and recyclability

- Hazardous substance disclosures per component

- Recycling technology development and submission of reuse/recycling performance reports (esp. for vehicles)

💡 Bonus: Korea allows participation in collective recycling schemes, which can reduce individual compliance burdens

Korea WEEE Requirements

Under the Korea RoHS Act’s WEEE chapter:

- Producers must manage their own take-back and recycling schemes (or join a PCS)

- Electronic waste must meet minimum recycling rates set by the Ministry

- Non-compliance can lead to fines or government-imposed cleanup mandates

Korea ELV Requirements

For end-of-life vehicles (ELV), importers and automakers must:

- Report vehicle recycling and treatment data

- Meet minimum material recovery rates

- Ensure proper hazardous substance handling during disposal

- Use registered, approved recyclers

Latest Korea RoHS Developments in 2025

What changed — and why it matters now:

Expansion of Regulated Products

As of 2025, RoHS + EPR applies to all EEE products, not just the original 49. Small manufacturers may be exempt, but everyone else must:

- Comply with hazardous substance limits

- Register products and submit compliance reports

- Participate in take-back or recycling schemes

New Recycling Targets for 2025

Mandatory recycling rates are now enforced for:

- 24 product types

- 5 packaging categories (e.g., plastics, metal housings)

These rates are tied to market share, and penalties apply if not met.

Korea RoHS Tougher Enforcement

- Penalties for violations (substance or recycling) have increased

- The Ministry of Environment now mandates compliance reporting + lab verification

⚠️ If your supplier reports aren’t aligned with Korea’s recycling laws, your product could be blocked at port.

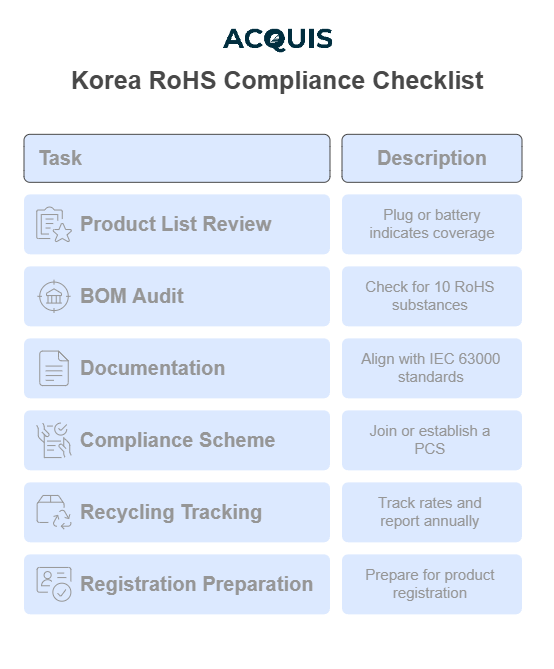

What Manufacturers and Importers Must Do to comply with Korea RoHS

- Review your product list: If it has a plug or battery, assume it’s covered.

- Audit your BOM for RoHS substances (10 total)

- Use IEC 63000-aligned documentation

- Join or establish a Producer Compliance Scheme (PCS)

- Track recycling rates and report annually

- Prepare for possible product registration in 2025

Acquis Makes Korea RoHS Compliance Automatic

Keeping up with Korea RoHS, WEEE, and ELV rules is no small feat. Acquis helps you:

- Flag high-risk components early

- Track all RoHS substances across your BOM

- Generate audit-ready documentation (IEC 63000)

- Manage WEEE and ELV take-back reporting

- Stay current with Korea’s MOE updates

Book a compliance walkthrough today with our Korea RoHS experts to ensure you’re ready for the next enforcement cycle.