Table of Contents

Responsible sourcing isn’t optional anymore. With rising regulatory scrutiny and growing stakeholder pressure, manufacturers must prove their supply chains are conflict-free—and that starts with knowing exactly who’s refining your minerals.

The Responsible Minerals Assurance Process (RMAP), maintained by the Responsible Minerals Initiative (RMI), offers a verified list of smelters and refiners that have undergone rigorous third-party audits. Whether you're reporting under the Dodd-Frank Act Section 1502, preparing your Form SD and Conflict Minerals Report (CMR), or simply trying to meet ESG expectations, the RMI Conformant Smelter & Refiner List is your first step toward transparency and traceability.

What Is RMI’s RMAP Participating Smelters and Refiners List?

The RMAP Smelter & Refiner List identifies facilities that have been audited and validated for responsible sourcing practices. It includes:

- Facility name and location

- Metal(s) processed (3TG: tin, tantalum, tungsten, gold)

- Conformance status (Conformant, Active, or Non-participating)

- Audit dates and reassessment schedule

This list allows downstream companies to make informed sourcing decisions and demonstrate due diligence to stakeholders, regulators, and customers.

Why the Smelter & Refiner List Matters for Conflict Minerals Compliance

- Ensures your minerals are not funding armed conflict

- Helps meet SEC disclosure and CMR expectations

- Supports ESG and sustainability reporting frameworks

- Reduces reputational, operational, and legal risks

Being proactive with smelter review shows your commitment to responsible sourcing and ethical business practices.

What Are Smelter Audits and Risk Assessments for CMRT?

A smelter audit evaluates whether a facility is sourcing minerals responsibly and complying with frameworks like the OECD Due Diligence Guidance. It typically includes:

- Documentation review

- Traceability checks

- Chain-of-custody analysis

- Site inspections (in some cases)

A risk assessment identifies and evaluates any red flags in your supply chain, such as:

- High-risk sourcing countries (CAHRAs)

- Suspicious ownership or management

- Gaps in supplier disclosures

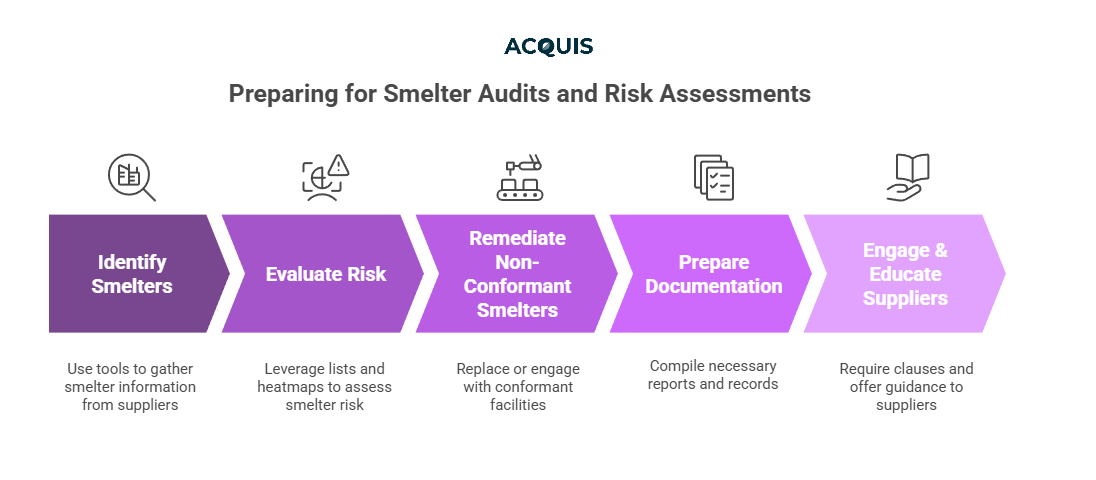

How to Prepare for Smelter Audits & Risk Assessments

- Step 1: Identify Smelters in Your Supply Chain

Use tools like the Conflict Minerals Reporting Template (CMRT) or supply chain tracing software to gather smelter info from your Tier 1 and Tier 2 suppliers.

- Step 2: Evaluate Risk Using Public & Proprietary Lists

Leverage:

- RMI Conformant & Active Lists

- EU CAHRAs List

- Acquis’s Smelter Risk Heatmap (if using Acquis software)

- Step 3: Remediate Non-Conformant Smelters

- Replace high-risk smelters where possible

- Work with suppliers to engage conformant facilities

- Track and document all remediation efforts

- Step 4: Prepare Documentation

- Smelter audit reports

- Supplier declarations

- RCOI process records

- Due diligence policies and training logs

- Step 5: Engage & Educate Your Suppliers

- Require conflict minerals clauses in contracts

- Offer guidance on CMRT/EMRT completion

- Share risk findings and expectations

Technology’s Role in Simplifying Audits

Modern compliance platforms like Acquis automate risk flagging, smelter validation, supplier outreach, and document management.

Look for Tools That Offer:

- Pre-integrated RMI Smelter Lists

- CMRT/EMRT survey automation

- Custom dashboards and real-time analytics

- AI-assisted smelter validation

How Acquis Simplifies the Process

- Centralized CMRT & smelter data tracking

- Auto-flagging of high-risk smelters

- Built-in conformity status from RMI

- Dynamic reports for SEC filing and stakeholder updates

Bonus: Our expert team guides you on engagement strategy, risk prioritization, and supplier compliance.

Strengthen Your Conflict Minerals Compliance

Whether you're starting your first RCOI or optimizing a mature program, Acquis helps you:

- Ensure smelter transparency

- Reduce supplier risk

- Automate Form SD compliance

Schedule a Demo to streamline your conflict minerals due diligence.