Table of Contents

The EU Battery Regulation (Regulation (EU) 2023/1542), which replaces the 2006 Battery Directive, is set to redefine battery sustainability, traceability, and compliance. One of the most significant requirements is the Battery Passport, which will be mandatory from February 1, 2027, for all EV and industrial batteries (capacity >2 kWh) sold in the EU market. If your company is involved in battery production, distribution, or use, you need to start preparing now. Let’s break down what this means, how it impacts compliance, and why ignoring it could cost you.

What is the Battery Passport?

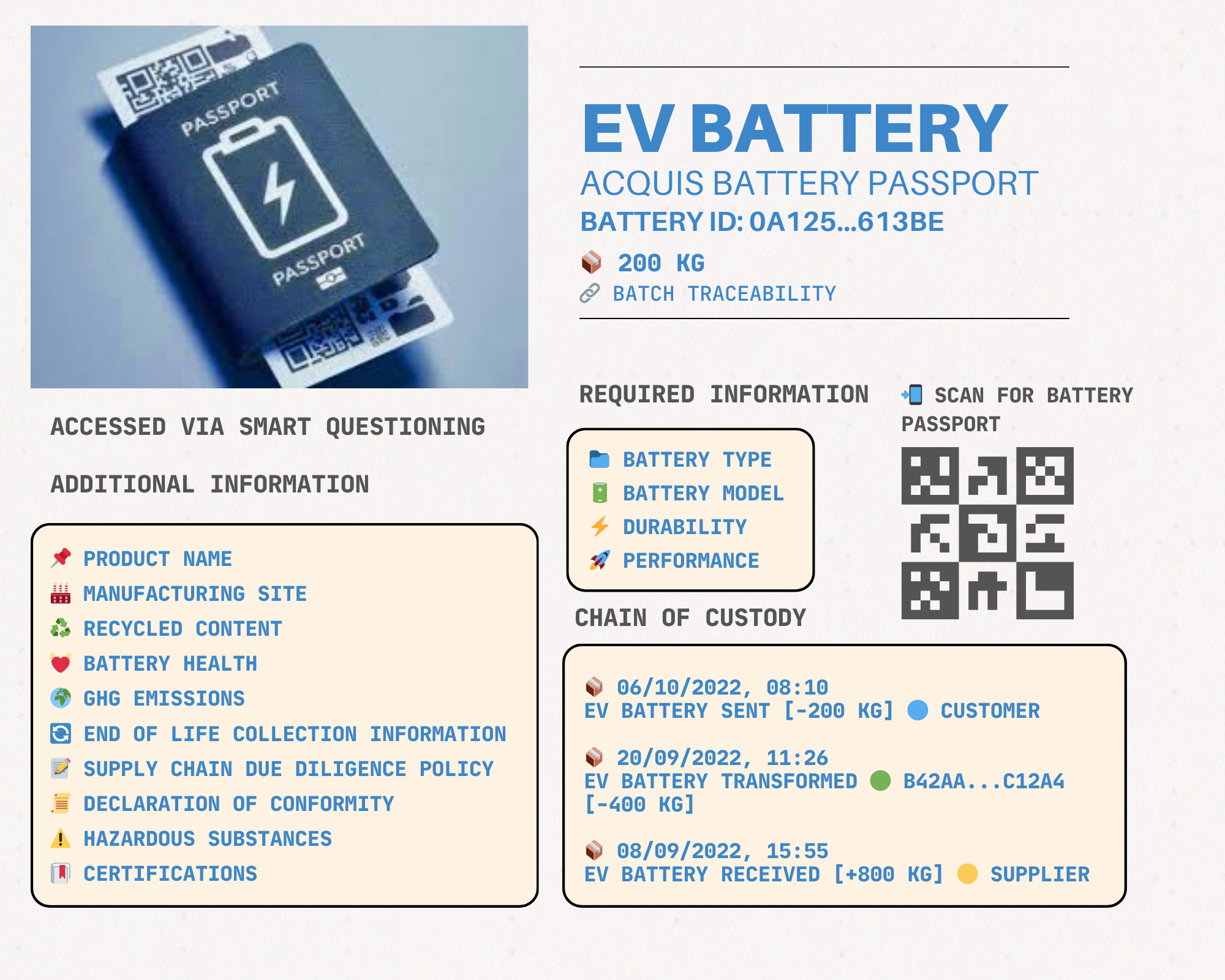

Think of the battery passport as a digital identity for each battery, carrying essential information throughout its lifecycle. Much like a vehicle logbook, it records key data related to production, composition, performance, and environmental impact. It ensures full traceability and aims to support sustainability goals by enabling efficient recycling and reuse.

From 2027 onward, every applicable battery must have a QR code that provides access to a digital record containing:

- Identification: Unique serial number.

- Technical Specs: Battery type, model, composition, production date.

- Performance & Durability: Lifecycle statistics, including charge cycles, energy efficiency, and degradation trends.

- Carbon Footprint: Emissions from production, verified by a third party, and categorized into performance classes.

- Recycled Content: Percentage of recovered materials (Cobalt, Nickel, Lithium, Lead) with verifiable tracking.

- Supply Chain Due Diligence: Proof of ethical sourcing, adherence to human rights obligations, and material traceability from extraction to final product.

- End-of-Life Handling: Information to facilitate repair, reuse, and recycling, including critical mineral recovery rates.

- Mandatory Data Fields per DIN DKE SPEC 99100:

- General Information: Manufacturer details, battery model, and serial number.

- Material Composition: Breakdown of raw materials and sourcing details.

- Environmental Impact: Carbon footprint, energy consumption, and sustainability metrics.

- Lifecycle & Performance Data: Charge-discharge cycles, safety test results, and durability stats.

- Recyclability & Disposal Information: Guidance on proper recycling and end-of-life management.

This standardized approach ensures that all stakeholders—from manufacturers to recyclers—have access to critical information, improving transparency and sustainability in the battery supply chain.

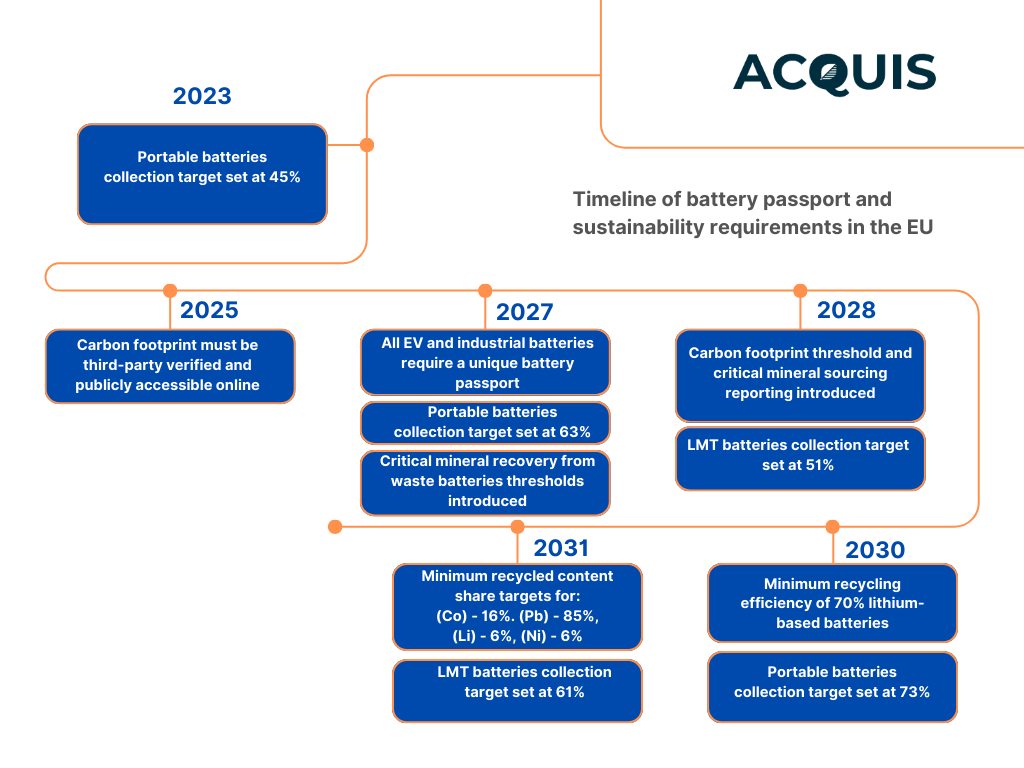

Compliance Deadlines: What You Need to Know

The EU is phasing in requirements leading up to full battery passport implementation in 2027. It is crucial to verify compliance with the most updated EU Battery Regulation framework, including potential amendments:

- February 2025 – Third-party carbon footprint verification for each manufacturing batch, including data from mineral extraction, cell production, and logistics.

- December 2025 – Minimum 65% recycling efficiency required for lithium-based batteries.

- December 2027 – Critical mineral recovery targets: Lithium (50%), Cobalt (90%), Nickel (90%), Copper (90%).

- February 2028 – Impact assessment for lifecycle carbon footprint compliance, including total emissions from battery production to disposal.

- December 2030 – Minimum 70% recycling efficiency for lithium-based batteries.

- 2035 and Beyond – Potential expansion to vehicle passports incorporating battery lifecycle data.

Stakeholders should regularly review updates from the European Commission and relevant regulatory bodies to ensure adherence to any new compliance deadlines or revisions in regulatory expectations. If you’re not tracking these milestones, you risk non-compliance—and that comes with financial, legal, and reputational consequences.

The Role of DIN DKE SPEC 99100 in Battery Passport Compliance

The recently released DIN DKE SPEC 99100 standard provides detailed guidance on the data attributes required for battery passports under the EU Battery Regulation. It helps importers, manufacturers, and distributors comply with data collection, storage, and reporting requirements but also presents challenges.

Comparison with Other Industry Guidelines

While DIN DKE SPEC 99100 sets a benchmark for battery data standardization in the EU, other regions and industry groups have also introduced similar standards:

- SAE J3071 (United States): Focuses on battery labeling, state-of-health monitoring, and traceability but lacks the extensive supply chain and sustainability requirements seen in the EU regulation.

- China’s Battery Recycling Regulations: Enforces strict material recovery targets, similar to EU goals, but currently lacks a unified digital passport system.

- ISO 14040/14044 (Global): Addresses life cycle assessment (LCA) methodologies relevant to battery production but does not specify data-sharing mechanisms like the EU Battery Passport.

Key Data Requirements in DIN DKE SPEC 99100

- General Information: Battery identification and manufacturer details.

- Material Composition: Information on battery materials and sourcing.

- Performance Metrics: Data on capacity, charge cycles, and lifespan.

- Sustainability Indicators: Carbon footprint calculations and documentation of raw material extraction conditions.

- Recycling and Reuse: Information on recyclability and traceability of battery components.

Challenges in Implementation

- Data Collection: Ensuring accurate data tracking across the entire battery lifecycle.

- Data Storage: Securely managing large datasets while maintaining compliance.

- Data Reporting: Implementing processes for seamless compliance with reporting obligations.

As regulatory frameworks evolve, businesses must remain agile in aligning with both regional and international standards to maintain compliance and market access.

The Risks of Ignoring Battery Passport Compliance

If a company fails to meet these requirements, the EU can block non-compliant batteries from being sold. This is serious because:

- Market Access Denial: Non-compliant batteries can be banned from the EU market, affecting revenue and business continuity.

- Legal Liability & Penalties: Under Article 69, businesses can be held accountable for damages caused by non-compliance—even if due diligence was attempted. Companies could face hefty fines, which vary by member state but can amount to a significant percentage of annual turnover.

- Mass Recalls & Financial Losses: Non-compliant batteries already placed on the market could be subject to recalls, incurring substantial costs for manufacturers and importers.

- Reputational Damage: Failure to comply could tarnish a company’s sustainability credentials and investor confidence, potentially leading to loss of business opportunities.

- Supply Chain Disruptions: Companies failing to meet supply chain due diligence may struggle to source compliant materials, affecting production timelines and partnerships.

- Increased Scrutiny & Compliance Audits: Regulatory authorities will conduct audits and investigations, which could result in mandatory corrective actions and additional compliance costs.

Conclusion: Get Ahead or Get Left Behind

The Battery Passport is not just another regulation—it’s a paradigm shift in how we track, use, and recycle batteries. With strict deadlines, companies cannot afford to delay implementation. Being proactive now will prevent costly disruptions later and ensure market access in the EU’s rapidly evolving regulatory landscape.

If you haven’t started preparing yet, now is the time to act. Reach out to our compliance experts to stay compliant