Table of Contents

California Proposition 65 is the most misunderstood compliance regulation in the United States and easily the most disruptive for article manufacturers. Most companies assume it only targets “chemicals” or “consumer packaging,” but the truth is far broader:

Prop 65 applies to any product, industrial, consumer, automotive, electronic, hardware, textile, tool, device, or assembly, if the product can expose a California consumer to a listed chemical above a defined safe harbor level.

This includes:

Prop 65 is not a niche regulation. It is a market access requirement for the world’s fifth-largest economy.

Why Proposition 65 Is Exploding in Importance (2025–2026)

Prop 65 is not new — it has existed since 1986 — but it behaves differently from REACH, RoHS, PFAS, TSCA, or Battery Regulation.

Prop 65 is accelerating for three reasons:

1. The List Keeps Growing Faster Than Manufacturers Can Track

The Prop 65 list now includes 1,000+ chemicals, including:

- phthalates

- lead

- cadmium

- nickel

- BPA

- acrylamide

- toluene

- flame retardants

- solvents

- plastics additives

- PFAS chemicals

- metals in solder and wiring

- combustion residues

Engineers often don’t know these are present because suppliers don’t disclose them voluntarily.

2. Enforcement in California Is Lawsuit-Driven

Prop 65 is enforced primarily through:

- private plaintiff attorneys

- consumer watchdog groups

- environmental NGOs

These groups aggressively target:

- retailers

- e-commerce listings

- importers

- distributors

- manufacturers placing products in California

Lawsuits frequently cost $25,000–$1.5M, even for simple labeling violations.

3. Most Products Cannot Meet Prop 65 Safe Harbor Levels

Safe Harbor Levels are extremely low — often parts per billion.

This means:

- trace contamination → labeling

- minor surface exposure → labeling

- small amounts in plasticizers → labeling

- legacy flame retardants → labeling

- solder joint exposure → labeling

If you cannot PROVE the absence of exposure, you must WARN.

Prop 65 Doesn’t Restrict Chemicals — It Demands Warnings

Prop 65 is NOT a ban. It is a mandatory warning if exposure exceeds a threshold.

The challenge is:

You must either: (1) Prove your product is safe, or (2) Apply the warning label.

Testing is expensive. Documentation is incomplete. Suppliers don’t know their chemistry. And lawsuits don’t wait for clarification.

This is why Prop 65 becomes a strategic decision, not a legal one.

Prop 65 for Article Manufacturers: The Core Problem

There is no global datasheet that reliably shows Prop 65 status.

Why?

- Most SDS are classified under OSHA, not Prop 65.

- Prop 65 substances may not be listed in SDS at all.

- Suppliers don’t test for California-specific exposure pathways.

- Safe Harbor Levels are not the same as presence thresholds.

- A chemical can be present below a threshold — but still trigger testing.

- Prop 65 includes inhalation, ingestion, dermal pathways.

This is why you cannot rely on:

- SDS

- material declarations

- EU compliance documents

- REACH SVHC lists

- RoHS data

- conflict minerals statements

Prop 65 is different from every other regulation.

Where Prop 65 Chemicals Actually Live in Articles (Engineering Map)

This is the real-world Prop 65 hotspot map across typical electronics and industrial-grade products.

1. Plastics, Polymers & Rubber Components

Common Prop 65 chemicals:

- phthalates (DEHP, DINP, DIDP)

- BPA + BPS

- flame retardants (TCEP, TDCPP)

- benzo[a]pyrene & PAHs

- styrene

- chlorinated paraffins

Found in:

- cable insulation

- connectors

- enclosures

- soft plastics

- grips and handles

- overmolded components

- gaskets and seals

- consumer device housings

2. Metals & Surface Treatments

Prop 65 metals:

- lead

- cadmium

- nickel compounds

- hexavalent chromium (in some plating processes)

Found in:

- solder

- plating

- connectors

- terminals

- electronic assemblies

- fasteners

- metal housings

- springs

Even trace surface exposure may require labeling.

3. Coatings, Paints & Surface Finishes

Includes:

- solvent residues

- epoxy curing agents

- flame retardants

- pigments

- chromium compounds

Found in:

- painted metal parts

- powder coatings

- UV-cured coatings

- screen-printed surfaces

- ink markings

- electro-deposited coatings

4. Adhesives, Sealants & Bonding Agents

Often contain:

- toluene

- formaldehyde

- acrylates

- isocyanates

- epoxy derivatives

Used in:

- assembly glues

- bonding layers

- display lamination

- cable terminations

- heat-resistant adhesives

5. Electronics Components

Critical Prop 65 hotspots:

- solder (lead exposure)

- PCB flux residues

- nickel-containing alloys

- flame retardants in PCB laminates

Prop 65 warnings are common for:

- headphones

- chargers

- cables

- power tools

- printers

- home electronics

- toys with electronics

6. Packaging & Labels

Packaging often triggers Prop 65 BEFORE the product does:

- inks & dyes

- adhesives

- recycled cardboard contamination

- flexible plasticizers

- PFAS in coatings

- flame retardants

Packaging is a lawsuit magnet because it is directly handled by consumers.

7. Anything That Generates Heat, Dust, or Fumes

If your product:

- heats

- abrades

- sheds dust

- releases fumes

- uses friction

- produces particulates

…it may create exposure where none existed in the raw material.

Prop 65 tests exposure, not composition.

Prop 65 = Exposure Pathways, Not Content Thresholds

Prop 65 doesn’t care what’s inside your product. It cares about what can expose a human, via:

- Dermal contact

- Inhalation

- Ingestion (e.g., hand-to-mouth for children)

This is why:

- A cable with DEHP → Warning required

- A consumer electronics device with nickel → Warning required

- A product with BPA in handles → Warning required

- A tool with lead solder under a housing → Exposure-based decision

If exposure is possible → label it.

Why Most Manufacturers Use the Warning Label

Realistically, manufacturers choose between:

Option A — Test every material

This is expensive, slow and incomplete.

OR

Option B — Issue a Prop 65 warning label

This avoids lawsuits but may hurt brand perception and restrict sensitive markets.

95% of companies choose Option B, unless they sell into:

- children’s markets

- medical markets

- premium consumer electronics

- clean-branding segments

- sustainability-sensitive sectors

Prop 65 Is Impossible to Treat as a “Compliance Form”

Prop 65 cannot be solved with:

- supplier declarations

- SDS sheets

- checklists

- certificates

- generic “compliance letters”

Safe Harbor Levels require:

- exposure modeling

- chemical identity verification

- manufacturing process insight

- material-level documentation

- surface transfer testing where relevant

This is why Prop 65 becomes a supply-chain risk-mapping problem, not a documentation exercise.

What Proposition 65 Actually Requires

California Proposition 65 (Safe Drinking Water and Toxic Enforcement Act of 1986) requires any company placing a product on the California market to:

- Determine whether the product exposes a consumer to any listed chemical.

- Compare that exposure to California’s Safe Harbor Levels.

- If exposure exceeds the level → provide a clear and reasonable warning.

- If exposure is unknown → you are still at risk and enforcement groups may sue.

Prop 65 is NOT:

- a chemical ban

- a substance restriction like RoHS

- a documentation exercise like REACH

- a reporting rule like TSCA

Prop 65 is exposure-based, which makes it fundamentally trickier.

The Prop 65 Chemicals List — What’s on It

Over 1,000 chemicals, including:

Metals

- lead

- cadmium

- nickel compounds

- hexavalent chromium

Plasticizers / phthalates

- DEHP

- DINP

- DIDP

- BBP

- DBP

PFAS (recognized category)

- PFOA

- PFOS

- PFHxS

- several PFAS considered carcinogens or reproductive toxicants

Solvents & industrial chemicals

- toluene

- benzene

- methylene chloride

- styrene

- ethylbenzene

Flame retardants

- TDCPP

- TCEP

- TBBPA (in certain contexts)

BPA & polycarbonate derivatives

Common in:

- food-contact items

- plastics

- coatings

Combustion byproducts / PAHs

Generated by:

- rubber

- some plastics

- heating elements

- friction

Formaldehyde & VOCs

In adhesives, foams, sealants, coatings.

Any one of these can trigger Prop 65 for a product category.

Safe Harbor Levels — The Real Compliance Trigger

The Prop 65 system works through:

- NSRL (No Significant Risk Level) → cancer

- MADL (Maximum Allowable Dose Level) → reproductive toxicity

If consumer exposure exceeds the NSRL or MADL → warning required.

These levels are often shockingly low.

Examples (real Safe Harbor Levels):

- Lead: 0.5 μg/day

- DEHP: 6 μg/day

- DINP: 146 μg/day

- Cadmium: 4.1 μg/day

- Formaldehyde: 40 μg/day (inhalation)

- BPA: 3 μg/day

Even trace release from:

- a soft cable

- a coated metal handle

- a small amount of dust

- a painted surface

- a plasticized grip

…can exceed those limits.

This is why article manufacturers require Prop 65 warnings.

Why Exposure Is Hard to Control in Finished Products

Exposure can happen through:

Dermal contact

- handling plastic grips containing DINP

- touching painted metal containing cadmium traces

- touching rubber parts containing PAHs

Inhalation

- adhesives off-gassing

- heated components releasing VOCs

- polymer curing agents

- flame retardant fumes

Oral transfer (children’s products)

- lead from surface coatings

- BPA leaching from plastics

- phthalates from soft materials

Because Prop 65 applies to practical use, not chemical composition alone, labs must test release, not just content.

This is what makes Prop 65 costlier and murkier than content-based regulations.

Prop 65 Enforcement — Why It’s the Most Dangerous US Compliance Law

Prop 65 is enforced by:

- The California Attorney General

- District attorneys

- Private enforcers — law firms that make revenue through Prop 65 settlements

- Environmental and consumer organizations

This enforcement structure means:

- They actively hunt for violations.

- They file lawsuits without contacting you first.

- They use e-commerce listings as evidence.

- They purchase products from Amazon, Walmart, Target, OEM websites, and test them.

- They target low-hanging fruit: electronics, toys, tools, hardware, accessories, packaging.

“Prop 65 lawyers” are not theoretical — they are an industry.

They file ~2,000+ notices per year. The average settlement ranges from $25,000–$250,000. Some go above $1.5M when multiple chemicals are involved.

This is why companies often use the warning label preemptively.

Prop 65 Warning Labels — The Reality for Manufacturers

Prop 65 warnings must follow the exact standardized format:

General Exposure Warning

WARNING: This product can expose you to chemicals including [CHEMICAL], which is known to the State of California to cause [CANCER / BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM]. For more information go to www.P65Warnings.ca.gov.

Short-Form Warning (allowed for small packaging)

WARNING: Cancer and Reproductive Harm — www.P65Warnings.ca.gov.

The short-form is the most widely used, especially for:

- electronics

- cables

- tools

- small products

- packaging components

Manufacturers use short-form warnings because:

- it avoids chemical-specific declarations

- it satisfies all categories

- it protects against lawsuits

- it reduces testing requirements

- it works across entire SKU families

Why California Is Different From Other States

No other US state has a system like Prop 65. Other states use:

- limits

- bans

- reporting

- broad chemical families

- PFAS phase-outs

But California uses lawsuit economics, which changes everything.

This creates four conditions:

1. Even compliant products can be sued

If your documentation isn’t legally defensible → lawsuit.

2. Testing does not guarantee safety

If the plaintiff’s lab gets a different test result → lawsuit.

3. Retailers pressure manufacturers

Retailers now require:

- Prop 65 compliance letters

- proof of warnings

- exposure assessments

- safety documentation

4. Prop 65 warning labels become the default strategy

Most global brands use the warning because:

- risk is too high

- testing is too expensive

- enforcement is unpredictable

- supply chains are nontransparent

Prop 65 “Gateway Products” — The Items Most Frequently Sued

These categories account for 70%+ of Prop 65 enforcement against manufacturers:

Electronics

- chargers

- headphones

- cables

- adapters

- power tools

- lighting

- appliances

- printed circuit materials

Common chemicals: DEHP, DINP, BPA, lead, nickel.

Plastic Goods

- toys

- handles/grips

- accessories

- consumer goods

- device housings

Common chemicals: phthalates, BPA, flame retardants.

Metal Goods

- jewelry

- tools

- hardware

- electronics connectors

Common chemicals: lead, nickel, cadmium.

Packaging

- flexible films

- colored boxes

- recycled cardboard

- adhesive labels

Common chemicals: ink PAHs, PFAS, phthalates.

Sporting Goods

- gloves

- foam pads

- grips

- rubberized materials

Common chemicals: PAHs, phthalates, flame retardants.

Prop 65 for OEMs and Contract Manufacturers: The Difficult Part

Even if you don’t sell directly in California:

- Retailers will demand compliance.

- E-commerce platforms (Amazon, Walmart) require Prop 65 documentation.

- Distributors will push liability upstream to you.

- Contract manufacturers will be forced to provide evidence.

Prop 65 obligations flow upstream.

If your customer needs a Prop 65 warning, they will require:

- your declaration

- your evidence

- your exposure assessment

Otherwise they cannot sell your product in California.

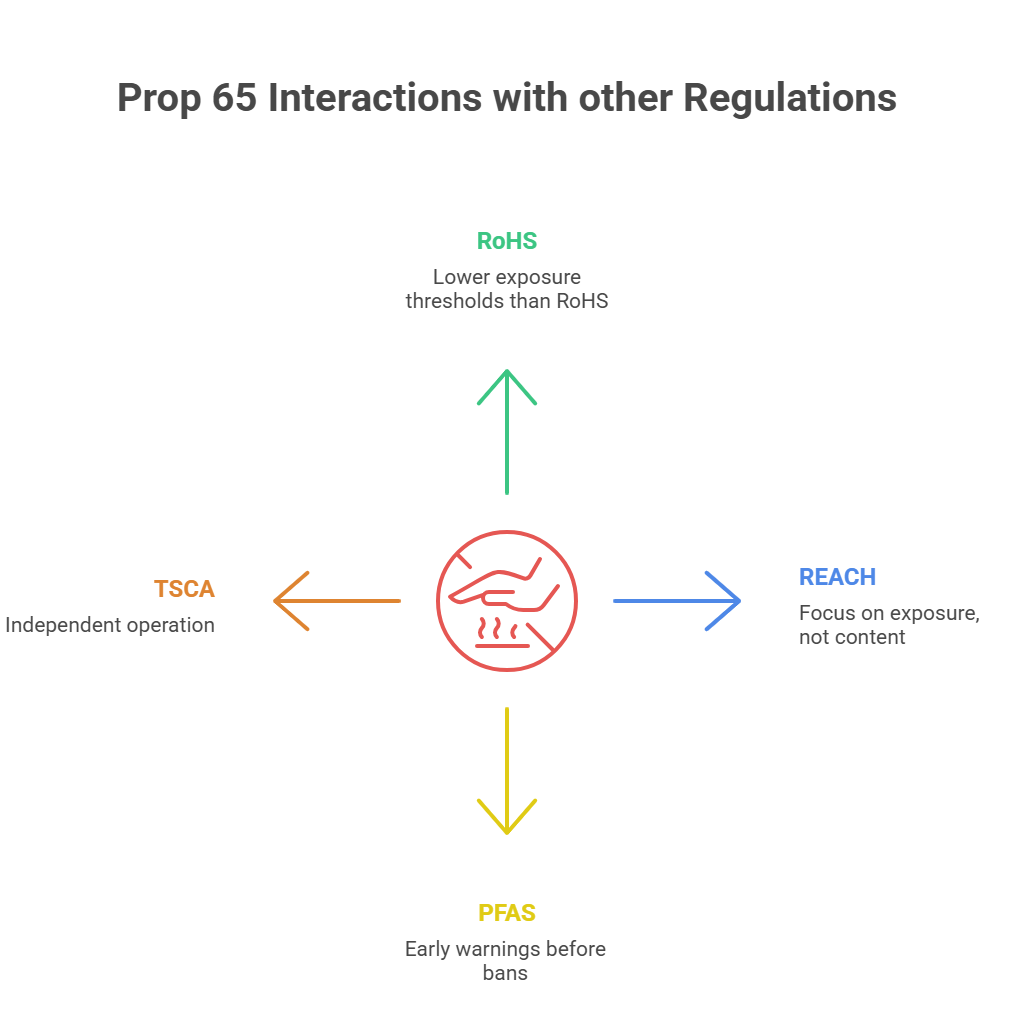

Where Prop 65 Intersects with Other Regulations

Prop 65 interacts with:

This is why Prop 65 must be treated as its own compliance system, not an extension of REACH or RoHS.

How Article Manufacturers Should Think About Prop 65 (Not How Lawyers Think About It)

Most legal summaries explain Prop 65 as:

“If exposure exceeds Safe Harbor Levels, a warning is required.”

This is technically correct but operationally useless.

Article manufacturers must think differently:

“Which materials or processes can create exposure — and can we prove they don’t?”

That requires:

- mapping exposure risks

- mapping materials chemistry

- mapping manufacturing processes

- mapping handling pathways

- mapping consumer-use scenarios

Prop 65 is a materials + use + exposure equation.

The PFEP Approach (Process–Formulation–Exposure Pathways)

Acquis uses a PFEP triage model internally:

1. Process

How the component is manufactured affects exposure:

- Is it plated?

- Is it coated?

- Is it soldered?

- Are solvents used?

- Was adhesive cured with heat?

- Are flame retardants added at compounding stage?

2. Formulation

What the material is actually made of:

- polymer + additives

- metal alloy composition

- coating chemistry

- ink formulation

- adhesive components

- curing agents

3. Exposure Pathways

How a consumer interacts with the product:

- touch

- friction

- heat

- inhalation

- ingestion (children’s products)

Prop 65 is only triggered when all three combine to create real exposure risk.

Engineering-Level Prop 65 Risk Map

Below is a real engineering-focused framework for mapping Prop 65 risks across a product BOM.

1. High-Risk Materials

These materials commonly contain Prop 65 chemicals:

| Material Category | Common Prop 65 Chemicals | Typical Products | | ------------------- | ----------------------------------- | ------------------------------------------- | | PVC & soft plastics | DEHP, DINP, DIDP | cables, toys, connectors, grips | | Rubber | PAHs, nitrosamines | shoes, grips, seals | | Polycarbonate | BPA | food-contact plastics, electronics housings | | Epoxy resins | BPA, BADGE | PCBs, adhesives | | Metal alloys | lead, cadmium, nickel compounds | connectors, springs, fasteners | | Coatings | formaldehyde, solvents, chromium VI | painted parts, printed graphics | | Adhesives | toluene, acrylates | assembly processes | | Flame retardants | TCEP, TDCPP | electronics, foams | | Packaging films | PFAS, phthalates, inks | retail packaging |

2. Medium-Risk Materials

Materials that may contain Prop 65 chemicals depending on formulation:

| Material Category | Possible Prop 65 Risk | | ------------------ | --------------------------- | | ABS plastics | pigments, brominated FRs | | Nylon | flame retardants, solvents | | Silicone materials | residual VOCs | | Urethane foams | TDI, MDI, flame retardants | | Recycled plastics | unpredictable contamination |

Recycled materials are especially problematic due to uncontrolled feedstock.

3. Low-Risk Materials

Materials unlikely to contain Prop 65 chemicals unless contaminated:

- glass

- uncoated stainless steel

- aluminum

- unfilled PP and PE

- ceramics

But contamination or coatings can still create exposure.

How to Actually Determine Prop 65 Exposure

Prop 65 isn’t about “ppm” or “content thresholds.” It’s about human exposure dose.

Prop 65 exposure =

(Chemical dose released per event) × (Number of daily events)

Exposure can come from:

Direct dermal contact

Example:

- DINP leaching from headphones or plastic grips

- Lead from solder residue on metal surfaces

Inhalation

Example:

- formaldehyde off-gassing from adhesives

- VOCs released from heated electronics

Oral transfer

Example:

- BPA from plastics

- Lead from children’s jewelry

Why Content Testing Is NOT Enough

Article manufacturers often make the mistake:

“We tested the material; it’s below detection → we’re safe.”

Wrong.

Prop 65 enforcement tests exposure, not content.

Example:

A plastic grip contains low levels of DINP (<0.1%), but if DINP can migrate through sweat/heat → exposure is above MADL → warning required.

Another example:

Lead solder inside a device might not migrate, but lead dust from machining or surface contamination can trigger exposure.

Labs use:

- migration tests

- simulated sweat

- simulated saliva

- thermal desorption

- inhalation/air chamber tests

- abrasion tests

These are far more aggressive than content testing.

Practical Exposure Scenarios Manufacturers Must Map

Here is a real list of exposure scenarios used in enforcement actions:

Touch scenarios

- children chewing toys

- adults handling tools

- users holding grips

- touching cables

Friction scenarios

- rubber grinding

- parts rubbing

- pads shedding dust

- polymer degradation

Heat scenarios

- chargers heating

- electronics warming

- adhesives off-gassing

- coatings emitting VOCs

Environmental scenarios

- UV exposure

- moisture

- sweat

- abrasion in outdoor use

This is why Prop 65 cannot be a checkbox — it requires engineering judgment.

Supplier Evidence: What You Should and Should NOT Ask For

Most manufacturers request:

- “Prop 65 declarations”

- “Prop 65 compliance letters”

- “SDS sheets”

- “A list of Prop 65 chemicals in materials”

These are worthless for risk protection because:

- SDSs follow OSHA, not Prop 65.

- Prop 65 chemicals may not appear on SDS at all.

- Suppliers don’t test exposure.

- Suppliers only know their input, not downstream exposure.

What to collect instead:

1. Full Material Disclosure (FMD)

At CAS-level, including additives.

2. Process chemical disclosure

Chemicals used in:

- plating

- adhesives

- coatings

- soldering

- lamination

- compounding

3. Curing and surface treatment details

- temperatures

- off-gassing profiles

- pre-treatment chemicals

4. Migration/abrasion data

If the supplier has done:

- migration testing

- VOC testing

- abrasion testing …you’re ahead.

5. Exposure modeling (rare but gold)

Very few suppliers can provide it, but it is the strongest evidence.

When to Test & When to Warn — The Real Decision Tree

Manufacturers use this internal logic:

IF the product is for children → TEST

Children’s products are lawsuit magnets.

Mandatory testing:

- lead

- phthalates

- BPA

- metals

- coatings

IF the product has soft plastics → LIKELY WARN

Unless you can prove:

- no phthalates

- no BPA

- no PAHs

- no PFAS

IF the product heats up → TEST OR WARN

Heat increases:

- migration

- off-gassing

- VOC release

IF any surface contains nickel → WARN

Nickel exposure risk is high.

IF the product is low-risk (glass, metal, ceramic, PP) → POSSIBLY SAFE

But coatings can break the assumption.

IF packaging contains inks/films/coatings → WARN

Most Prop 65 lawsuits begin with packaging, not the product.

Prop 65 Testing Decision Flow (Used by Large OEMs)

-

STEP 1 — Identify High-Risk Materials PVC, rubber, adhesives, coatings, pigments, platings.

-

STEP 2 — Map Exposure Pathways Touch, heat, friction, handling.

-

STEP 3 — Check FMD + supplier disclosures CAS-level details.

-

STEP 4 — Triage the product into Low/Medium/High risk Based on BOM.

-

STEP 5 — For High-risk components → lab test Migration, VOC, abrasion, heat testing.

-

STEP 6 — Compare lab values to Safe Harbor Levels

-

STEP 7 — Decision

- If below Safe Harbor Levels → document + NO warning

- If above → apply standard warning

- If unclear → apply short-form warning

This is how most global OEMs survive the regulation.

How Acquis Automates This (Manufacturer Reality)

Acquis builds an intelligent PFEP-driven Prop 65 workflow:

1. Smart Material Recognition

Acquis identifies:

- PVC

- rubber

- adhesives

- coatings

- pigments

- PCB materials

- plating chemicals

- packaging films

2. Auto-mapping to Prop 65 risk categories

Based on:

- migration risk

- exposure pathways

- known high-risk chemistries

3. Supplier documentation enrichment

Acquis requests:

- FMD

- process chemicals

- curing agents

- test reports

- VOC profiles

- plating details

4. Exposure-driven decision support

The system suggests:

- test

- no test

- warn

- retest

- seek new FMD

- substitute material

5. SKU-level Prop 65 labeling automation

Ensures consistent labeling across:

- packaging

- inserts

- e-commerce listings

- manufacturing documentation

This allows brands to reduce lawsuits, not just generate paperwork.

Designing Out Prop 65 Chemicals — The Strategic Approach

Prop 65 compliance is not just a labeling decision. Forward-looking manufacturers treat it as:

1. Brand protection

Avoid the “WARNING: Cancer and Reproductive Harm” message on every California SKU.

2. Material innovation

Move to next-gen polymers, coatings, and additives.

3. Supply-chain modernization

Shift suppliers from “trust me” to CAS-level transparency.

4. Litigation shield

Remove high-risk exposures entirely, not just defend them.

This section gives you the actual engineering rules that OEMs use to remove Prop 65 chemicals proactively.

Engineering Substitution Playbook (Material-by-Material)

These substitutions reduce Prop 65 exposure and protect your brand from litigation.

PVC (DEHP, DINP, DIDP) → TPE or TPU

PVC is the single biggest Prop 65 risk due to phthalates.

Better alternatives:

- TPE (thermoplastic elastomers)

- TPU (thermoplastic urethane)

- Silicone blends

- Phthalate-free PVC (only if supported with CAS-level formulation)

Use cases:

- cables

- grips

- toys

- flexible components

Most global brands have eliminated phthalates entirely.

Rubber with PAHs → Thermoplastic Elastomers

PAHs migrate easily, especially in warm/humid environments.

Better alternatives:

- TPE

- EPDM blends

- medical-grade silicone

Avoid recycled black rubber unless fully certified.

Polycarbonate with BPA → BPA-Free PC or Tritan™

BPA is a reproductive toxicant under Prop 65.

Alternatives:

- BPA-free polycarbonate

- Tritan™ copolyester

- PETG (non-food-contact electronics)

Useful for:

- electronics housings

- eyewear

- durable consumer goods

Epoxy resins with BPA/BADGE → Halogen-Free / BPA-free Epoxies

Especially relevant for PCBs and coatings.

BPA-free epoxies reduce both Prop 65 and PFAS concerns.

Lead in metals → Lead-Free Alloys

Critical for:

- connectors

- solder

- fasteners

- metal housings

Lead-free solder (SAC305, etc.) is already the standard. However, surface contamination remains a Prop 65 risk — require post-cleaning certification.

Nickel exposure → Nickel-Free Plating Systems

If nickel touches skin → Prop 65 warning.

Alternatives:

- trivalent chromium

- PVD coatings

- electroless nickel with sealant (lower migration)

- nickel-free stainless formulations

Solvent-based adhesives → Water-based / UV-curable adhesives

Toluene, hexane, methylene chloride are high-risk.

Switch to:

- UV-cured acrylates

- water-based adhesives

- low-VOC systems

Flame retardants (TCEP, TDCPP) → Non-halogenated FR systems

Use:

- aluminum hydroxide

- magnesium hydroxide

- phosphorus-based

- inherently flame-resistant polymers (PPS, PEEK)

PFAS coatings in packaging → Non-fluorinated barriers

PFAS in packaging is a growing litigation category.

Alternatives:

- silicone-based

- acrylic dispersions

- EVOH

- bio-based waxes

Prop 65 Design Rules — What Engineers Must Apply

These are the actual rules used by top electronics and consumer-product brands.

Rule 1 — No soft PVC unless supplier provides FMD + phthalate-free certification

PVC = guaranteed phthalate exposure unless proven otherwise.

Rule 2 — No unverified black rubber

Black rubber almost always contains PAHs.

Rule 3 — No nickel-touching surfaces

If a consumer can touch it → it requires a warning.

Rule 4 — No solvent-based adhesives in heated areas

If the product warms:

- adhesives off-gas

- VOC inhalation pathways trigger Prop 65

Rule 5 — No BPA in any consumer-touch component

Especially:

- handles

- buttons

- food-contact

- children’s items

- electronics with plastic shells

Rule 6 — Avoid recycled materials unless certified

Recycled plastics often contain:

- phthalates

- PAHs

- heavy metals

- unknown additives

Rule 7 — Remove PFAS-based coatings from packaging

PFAS litigation is accelerating in California.

Rule 8 — Use halogen-free, low-VOC coatings

Paints & coatings are lawsuit hotspots.

Rule 9 — Ensure solder surfaces are sealed and cleaned

Lead and nickel residues from solder splash or flux can trigger dermal exposure.

Rule 10 — For any high-risk material, assume WARNING unless proven otherwise

Prop 65 rewards over-protection, not minimal proof.

Prop 65 Roadmap for Article Manufacturers (6–12 Months)

Here's the real roadmap global OEMs follow.

Phase 1 — Rapid Risk Assessment (0–30 Days)

- inventory all materials

- identify high-risk categories

- classify SKUs into Low/Medium/High risk

Acquis automates this step.

Phase 2 — Supplier Chemical Transparency (30–90 Days)

Request:

- FMD

- process chemicals

- additive packages

- coating formulations

- plating specs

- curing temperatures

- migration data

Most suppliers will fail. That’s normal — continue to Phase 3.

Phase 3 — Test High-Risk SKUs (60–150 Days)

- migration tests

- VOC/off-gassing

- abrasion

- thermal desorption

- children’s product testing

Phase 4 — Decision Framework (90–180 Days)

For each SKU:

- warn

- test

- redesign

- substitute materials

- gather more data

Short-form warning is the fallback.

Phase 5 — Material Substitution (180–365 Days)

Apply engineering rules:

- eliminate PVC

- eliminate BPA/BPS

- eliminate PAHs

- eliminate solvent adhesives

- redesign nickel surfaces

- remove PFAS from coatings

Phase 6 — Acquis Automation Build-out

Implement:

- supplier upstream data collection

- FMD ingestion

- document intelligence

- PFEP risk score

- SKU-level labeling engine

- version-controlled audit trail

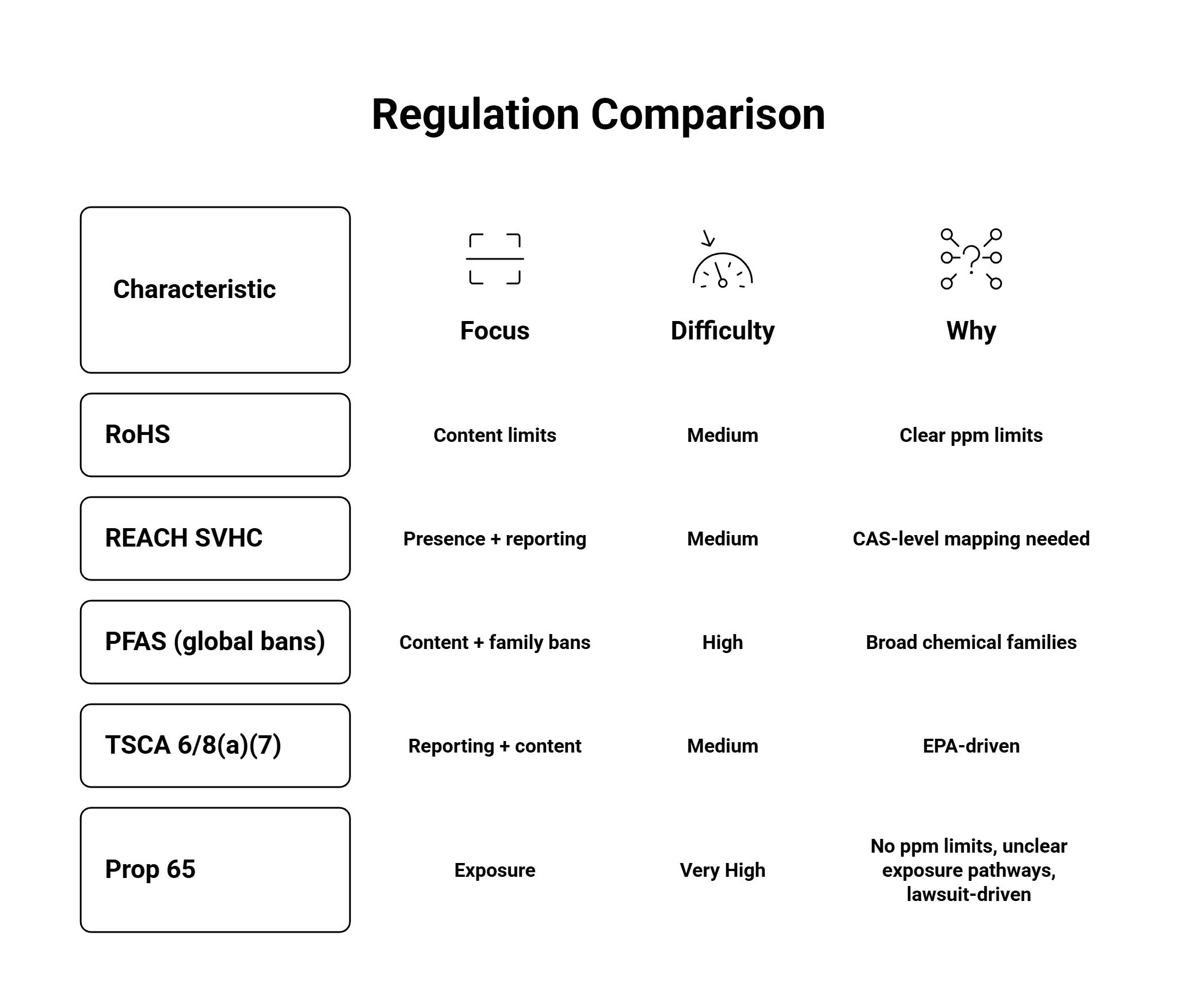

Prop 65 Compared to PFAS, REACH, RoHS

Prop 65 is the least predictable and most expensive regulation for OEMs — unless it is systematized.

How Acquis Operationalizes Prop 65 at Scale

Acquis deploys a structured engine optimized for article manufacturers:

1. Document Intelligence (DI)

- extracts ingredient-level chemicals

- flags high-risk chemistries

- identifies additives

- recognizes plating/coating patterns

2. Supplier Engagement Engine

- sends structured FMD + process-chemistry requests

- automates follow-ups

- validates supplier responses

- enriches missing CAS numbers

3. PFEP Chemical Risk Scoring

Scores components based on:

- polymer chemistry

- exposure likelihood

- known additives

- toxicology data

- material behavior (migration, off-gassing, dermal transfer)

4. SKU-Level Prop 65 Warning Decisioning

The platform tells you:

- Test this SKU

- Don’t test this SKU

- Warning required

- Retest needed

- Substitute material

5. Acquis Label Engine

Generates:

- warning text

- packaging instructions

- e-commerce text

- documentation record

6. Audit Trail

Every decision is logged:

- supplier data

- FMD

- test results

- exposure assessments

- exceptions

- labeling decisions

This creates a defensible compliance record.

Conclusion — What Prop 65 Means for Article Manufacturers

Prop 65 is not a chemical problem. It is:

- a material science problem,

- a supply-chain transparency problem,

- an exposure physics problem, and

- a litigation risk problem.

This master hub gives your engineering, sourcing, and compliance teams:

- the substitution playbook,

- the decision tree,

- the exposure modeling logic,

- the supplier evidence structure,

- the SKU-level triage model,

- and the Acquis automation engine.

This is how leading brands avoid lawsuits, protect the brand, support customers, and scale product safety documentation across thousands of SKUs.